Coffee Bar/Hutch

By The Wood PastorClean counters means a clean home…maybe. I hate clutter on the countertops in the kitchen. My wife and I also liked the idea of a coffee bar holding all of our coffee “things” separate from the kitchen countertop. We played with the idea for a year, and then finally designed and built one we love.

Directions

-

Cut Your Lumber

If you don't have a table saw with an out feed table, the Kreg Rip Cut is great to use with a circular saw to dimension your lumber. Theres many ways to set it up. Here I simply set the blade a little more than 3/4" to cut through the plywood, but not through the table. Other builders have put a piece of foam underneath to not cut into their table top. I don't mind though. I'll be making my large sheet cuts with this, smaller strips with a table saw, and finally a miter saw for the length cuts.

-

Base Cabinet Cuts

Once you cut all of you lumber from the cut list, your base box, unassembled, will look something like this. You have the bottom shelf, two walls, the 9" backer, the front support, and two extra pieces for drawer supports explained later.

-

Sides of the Base

Before you ever start assembling, be sure to sand all sides of your plywood and pieces to 150 grit. Choose a side you think is the nicest and face it in or out. Here I drew a line 5" from the bottom with a straight edge. Accuracy is key or your cabinet will be a little off.

-

Bottom and Sides

Make sure you connect the bottom shelf underneath the previous two lines drawn. This will help you keep everything measured right for later. You can use a Kreg Pocket Hole Jig for the bottom shelf here. I work at a cabinet shop, so I tend to use a 16 gauge brad nailer to connect a lot of my pieces. There's many ways to assemble this. Here's mine.

-

Back Support

This 9" backs support will be attached flush to the top and the back of the cabinet. I used at brad nailer again, but you could also pocket hole this. The reason it's 9" is for a reason. It will help keep you in line with your drawers on your face frame later on in the build. I also use no glue on most the assembly. That's kind of cabinet 101. In case you need to take something apart. All these piece help square up and support your cabinet as well.

-

Front Support

This top support will be flush to the front and the top as well. You can connect it with brad nails or pocket holes. If you connect it with pocket holes you won't have to putty or bondo the outside of the plywood walls when finishing later.

-

Toe Kick Block

Here the base is on it's back. Measure back 2" as shown in the picture. I usually mark a line. I will undercut the support block by 1/16" just to make sure it does hold the cabinet up higher than it needs to be when its completely finished. You can skip this step if you choose to pocket hole the next step.

-

Toe Kick Blocks

Here's what it should look like if you attach both. I used staples here that were 1" long. Make sure you attach these with something about the same length but definitely no longer than 1 1/4".

-

1/4" Back Base

Right now the cabinet is face down. Things move and 3/4" plywood is never true. So I usually wait to measure the backer during assembly. I choose not to go all the way to the floor with it because there's no need. Measure top to bottom shelf, and side to side. Then undercut it by 1/16" to make sure it sits inside the plywood edge. This piece should be 30 15/16" by 29 3/4". And attached with 1/2" staples.

-

1/4" Back Attached

This is how she looks attached. By she I mean the 1/4" back.

-

Hutch Cuts

If you succeeded assembling the base, this will be a breeze. It's just two sides, and three shelves, one acting as the top of the cabinet. You can take one out or add as many shelves as you want depending on your final vision for this project.

-

Hutch Sides and Shelves

All the shelves are attached here and the top. I used a 16 gauge brad nailer here as well, but could be subbed for a few pocket holes and easier to finish later as well. I made sure the bottom shelf was 26" high to fit our grind and brew coffee maker. This was personal preference for me. I also made sure each shelf had a 7" space to keep things symmetrical. Be careful when measuring here for symmetry. The face frame that will be attached has about 1 1/4" overhang from the top. So be sure to account for that.

-

1/4" Back Hutch

Just like with the base, measure top to bottom and under cut by 1/16" and attach with staples. This piece should measure about 24" by 41 7/8". Something you'll see different here is I marked where the fixed shelves are and also stapled from left to right. Be careful you don't blow through the back of the 1/4". So measure twice before committing. This will make the 1/4" back a lot more stable.

-

1/4" Back Hutch Attached

a

-

Toe Kick Runner

Here the toe kick runner is attached and should be about the same length as your bottom shelf. Maker sure it does not run big and push the side walls out. If it's a tiny bit short it won't matter because you'll cover up the gap and staples later. Ignore the plywood top for now and the fact the 1/4" back is already on.

-

Face Frame Cuts

All my face frames are cut with a miter saw as seen here for accuracy. It's easiest to measure and cut them all at once, and then assemble them all at once as well before attaching to the base box and the top hutch. All the measurements are on the cut list page.

-

Face Frame Lumber

All your face frame pieces should look about like this. I chose to use Rainbow Poplar (aka Sexy Poplar) which has some purple and black in it. You can use any species wood that best suits your needs.

-

Base Face Frame

Here's the back side of the base face frame. Your spaces should be 5", 9 5/8" x 2, and a 3 1/2" space on the bottom for the final toe kick.

-

Base Face Frame Attached

If you're happy with your face frame, go ahead and attach it to your base box. Every edge should be flush or close to it. If your face frame is a little bigger that's ok, just split the difference and make sure you have equal overhand on each side. It shouldn't be much. Before attaching spread some titebond glue over the plywood face and then lay the face frame over the top of it directly. Attach with 16 gauge brad nails 1 1/2" length.

-

Toe Kick Corner

Now that you have the face frame attached you can attach the final toe kick piece. This is all for looks and they way we do it at the company I work for. I love it and so do others. But there are many other toe kick options out there and this plan can be modified to fit that. This piece is 2 7/8" long on the front and mitered to 45 degrees on the back to make a small trapezoid. This is easiest to do on a miter saw and start with a longer piece, flip that piece after measure down the stick of wood, and then cutting the second miter. I'd rather it be a little short than a little high. It'll blend that way. Attach with brad nails and wood glue.

-

Toe Kick Corner 2

Here is a better shot of what it looks like attached and complete.

-

Hutch Face Frame Attached

Next attach the hutch face frame using all the previous information for attaching the base face frame. Make sure the shelf pieces are flush with the top of the shelves. If you are a little off you can bump it up or down with a rubber mallet as to not damage the plywood. Attach with 16 gauge nails and wood glue.

-

Base Table Top

For the table top of the base cabinet I glued up 4 pieces of white oak and trimmed it all to size. This may be out of the range of a beginner in woodworking, but I do know you can find larger pieces of pine glued up for projects at local big box stores. If not, you can always use plywood cut to size and attach edge banding or make your own, similar to the face frame thicknesses.

-

Bondo Plywood Holes

If you are painting your pieces I recommend using a two part bondo with a hardener. This is awesome for filling holes and hiding that you ever made one. after it hardens, sand it down to 150 to match all your other work pieces.

-

More Bondo

Do the same on your base cabinet if you are painting. If you are staining you can use wood putty that matches the plywood type you are using. Here I'm using maple plywood and it's already been primed.

-

Saddle Supports

These are saddle and drawer supports. These will fit at the back of your base cabinet on the right and left side. The little squares are 2" by 2" pieces that mimic the second from the bottom face frame piece on the base cabinet. Basically they will be level with the face frame. Attach the squares 9 5/8" from the bottom of the whole piece, but make sure they fit under your 9" back piece. The long pieces should be about 21 1/4" long. You will also make a 2" by 27" support and attach it flush to the bottom of the 9" backer support. There's pictures at the beginning and towards the end of the build that show this step complete as well.

-

Rip and Cut all OSB for Drawers

I chose OSB for this project inside the drawers for fun. Typically people will use 1/2" plywood. This is a lot less expensive and is also still 1/2". Make sure you cut your pieces to the size on the cut list.

-

Dado Grooves in Drawers

Once you get all of your pieces cut to length and width, you will use a table saw or set up a router to "Dado" a groove into your pieces. This groove will be 1/2" high and 1/4" deep and wide. Since the blade on a table saw is 1/8" wide you may have to run all of them through once, move the blade 1/8" over and run them all again to equal 1/4". If you have a Dado Stack then you probably already know what you're doing. Join your pieces together with 1" staples, but make sure you do not staple the grooves, because they will need to have a 1/4" piece slide in later. You will only staple 3 pieces together until you can slide the bottom panel in, then finish by adding the front last.

-

1/4" Bottom and Front

This should make more sense seeing it now. Notice some pieces are inset. That is the front and back pieces to the drawer. The sides will always run the full length of the drawer. On this project all of the 24" pieces will be the fronts and the backs (6 of these) while the side pieces will be 22" (6 of these).

-

All Drawers

Here's what all the drawers will look like assembled. One small drawer and two larger drawers with all the 1/4" slid into place, stapled, and square.

-

Staple the Bottom

Now this is a controversial step. I love this, but it's been questioned by others. To stay true "this is how I do it". Make sure you have something square for reference. I stapled 3/4" pieces to my table in the shape of an L. That's my reference. Now I'll push the drawer into the L piece and maker sure it's square. It'll be close, but you'll find a lot of the time the sides may be bowed out a or in a bit. Pull the drawer into the corner with one hand closing that bow or gap. With the other hand shoot 1/2" staples in the corners at 45 degrees. Go slow until you get into a rhythm. This will completely square the drawer up and hold the 1/4" bottom in place not allowing it to slide or waiver at all. You're Welcome.

-

Saddles

This is another controversial step added for drawers instead of directly screwing your slides to the walls of your cabinet. These are called saddles. They are 2" wide and 21 7/8" long times 6. You'll have 3 rights and 3 lefts. DO NOT make all 6 of these exactly the same or you'll have to flip 3 later. Take the "guts" of the drawer guides out and attach these flush to the bottom of the saddles and the front should overhang 1/2" but no more than 3/4" or it'll push out passed your face frame later. Attach all the guides as seen here but with 1/2" screws. They have set spots for you.

-

Saddles Assembled

Your saddle back pieces will all be 26" long and inset to the sides of the saddle. Use 1" staples to assemble the joints. The finished saddles should look like this and you'll have 3 exactly the same.

-

Saddles Attached Inside

Once the saddles are in place screw them into the sides of the face frame where they overlap with 1/2" screws. The back of the saddles should rest on the bottom shelf and the supports made and attached earlier. Once the drawers are put together with fronts on, you'll make sure the saddles are sitting square with the cabinet. You'll know this because there will be no gaps with the drawer is shut and the drawer front will hit the face frame evenly all the way around. Once you do this later, you'll shoot a few short nails, staples, or screws into the saddle at the back into the supports. This will keep the drawer from tipping forward when you load it.

-

Drawers Attached Inside

When you pulled the guts of the guide out earlier, you'll need to attach those pieces to the drawers. The guts or drawer guides will be flush to the front of the drawers but sit 1/4" from the bottom of the drawer. This will make sure the guides fit back together perfectly and don't drag the face frame. Most guides come with a step by step process on what this looks like as well.

-

Drawers Attached 2

Here is another picture with all of the drawers in place with the guides and saddles.

-

Kreg Jig Pocket Hole Face Frames

Kreg Tool has several different options when it comes to pocket holes. This is the single, and I've used it from day one, mainly because it's effective, I can travel easily with it. Kreg has many other set ups at a good price to help you drill pocket holes easily. This is my way. They come with a template on how deep you need to set your collar on your step bit and what size screws to use depending on joinery. I used all 1 1/4" screws for this whole project. Your next step is to drill all your pocket holes on all of your horizontal face frame pieces. DO NOT put any pocket holes in any of the vertical pieces.

-

Assemble Face Frames

One of the easiest ways to make sure your face frame pieces remain flush is to clamp the joint in the middle and to clamp it directly to the table. Before I clamp these and attach, I make sure to add a little titebond glue to the joint first for extra strength. Attach all face frame piece according to the sketch show in the pictures.

-

Chamfer Drawer Fronts

Once you've cut the drawer fronts to size from the cut list you can add a detail with a router or leave it square. I chose to chamfer mine all the way around. Your drawer fronts should measure an inch longer and wider than your drawer opening in the face frame. With this you'll have 1/2" overlay all the way around the face frame.

-

Nail Drawer Fronts

Typically you can use a jig to attach the fronts to the body of the drawer. But here I simple measured 1/2" outside the face frame, put a small mark, held the drawer up to the marks I made with a pencil, and then shot a 1 1/4" brad nail in all four corners of the drawer. This will assure the front is square on the cabinet and hold it, until you can take the drawer off and ad screws from the inside to attach it more securely.

-

Screw Drawer Fronts

Here is a picture of how I screwed the drawer fronts on from the inside of the drawer. I used 3/4" screws for this since the body is only 1/2" of material. It wouldn't hurt to use 1" screws, but I didn't have any.

-

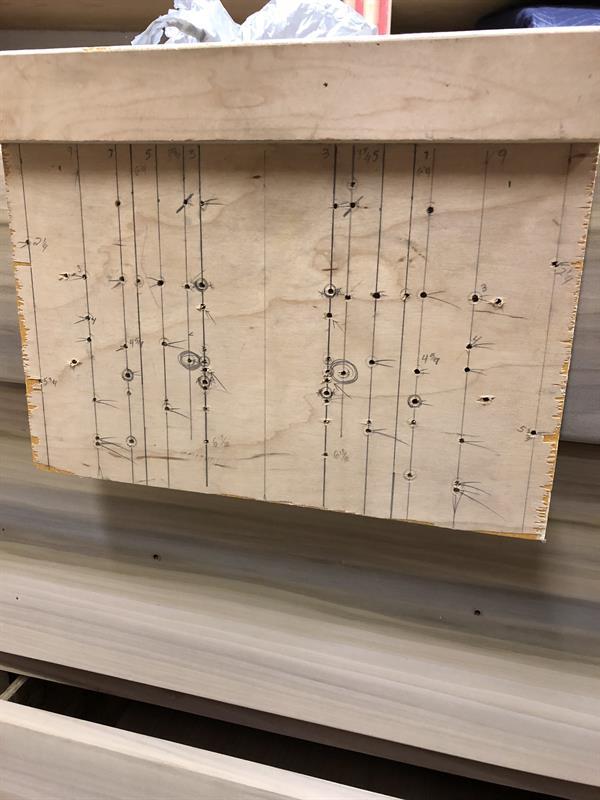

Hardware Jig

Next you'll need to drill for your hardware. This is a simple jig that sits on the top of the drawer and it allows me to find center and choose the width of the hardware. On the 6 inch front I want to be center from side to side and make sure I'm only 3" down. Which would be center as well. I believe my handles were long and had a 9" spread or gap between the holes. You can throw the jig method out and individually measure each handle, but this is an easy way for me and repeatable.

-

Drawer Hardware

This is what the hardware looks like attached that I choose for the bottom section.

-

Tape Hutch Paint

On my build I chose to leave the face frame natural and paint every piece of plywood. My wife and I like natural and neutral colors so we went with a light gray. Taping off the face frame just gives me a clean line when removed.

-

Tape Base Paint

We did the same thing on the base here.

-

Kreg Jig Pocket Hole Base Walls

Jumping to the base. Something I didn't do here was add pocket holes before assembling the face frame and drawer guides. Do this now or even before you assemble the entire box! I don't usually attach my tops this way but I am going to a lot more often. That's one reason I didn't think of it until later. You can use brackets, glue, or even brad nails if you don't go this route.

-

WOW!

And here is the finished product before we ever loaded it up with coffee and loaded the drawers! We both love it and I hope you do too. If you have any questions about any of the measurements just message me and let me know.

-

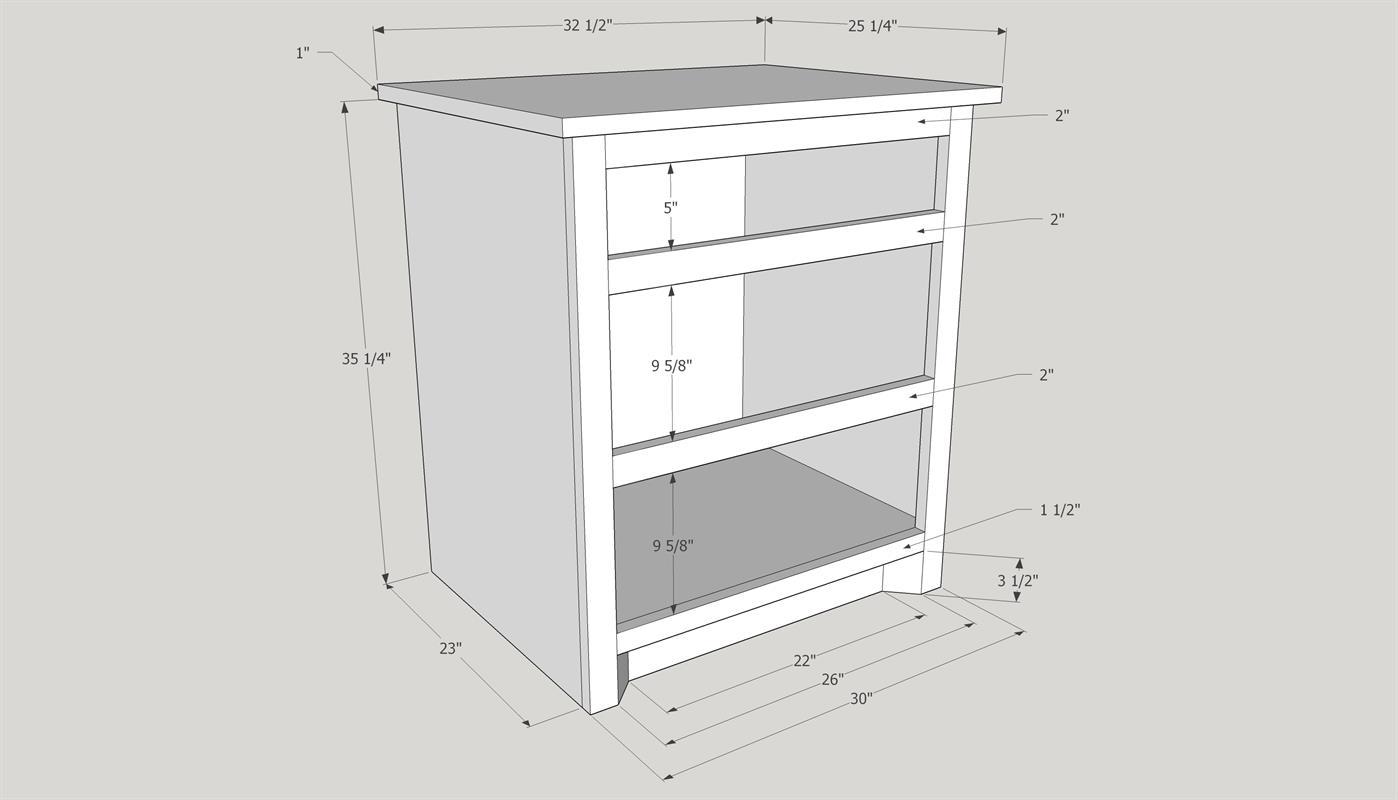

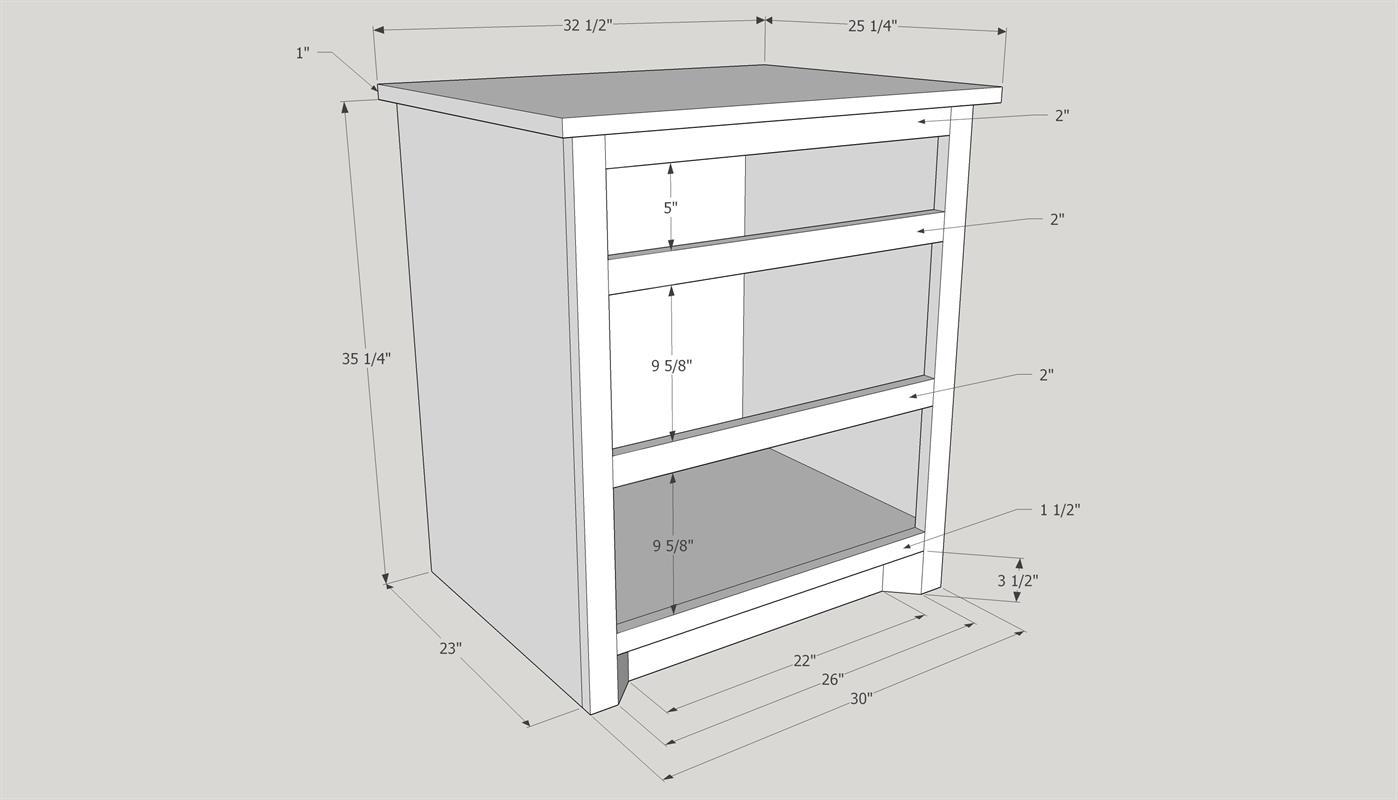

Sketch Up Base

Sketch Up Base

-

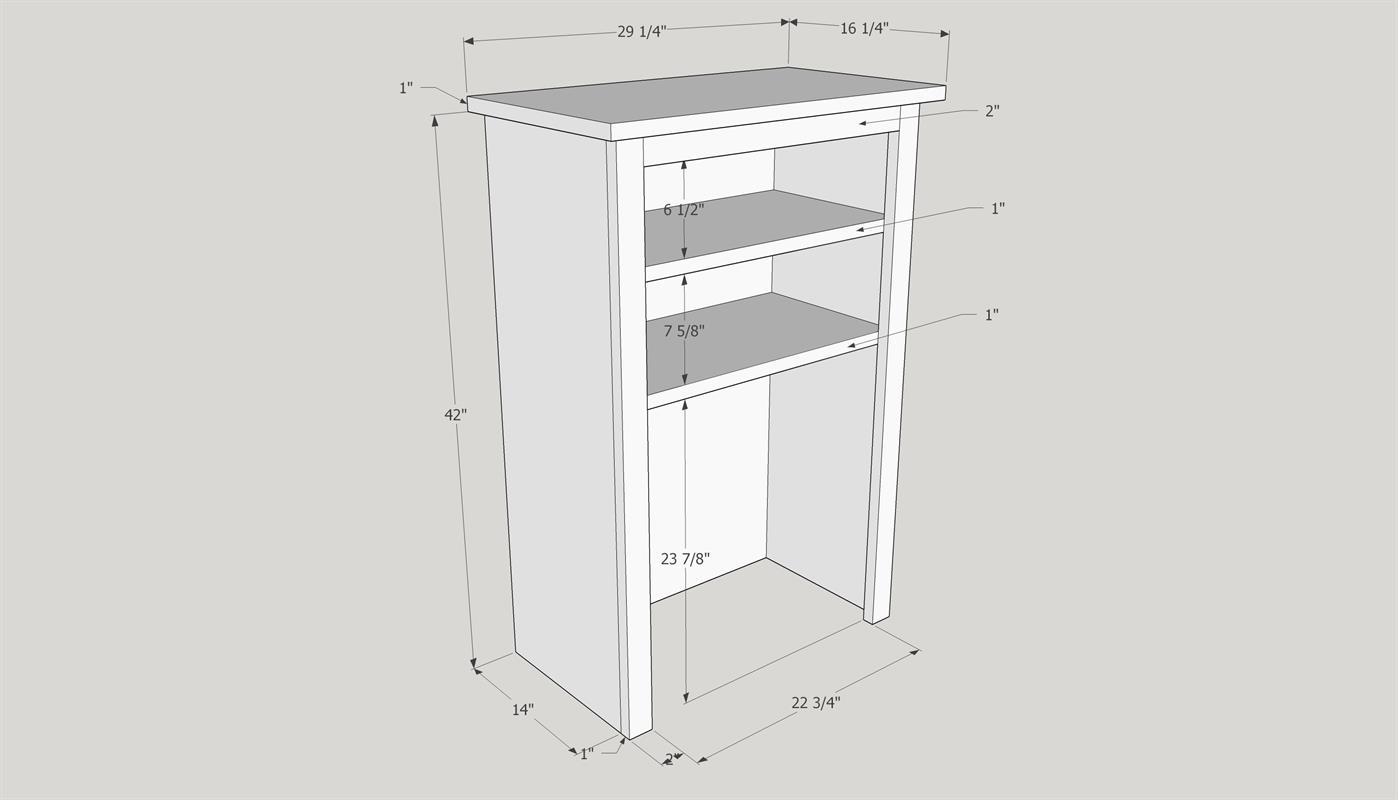

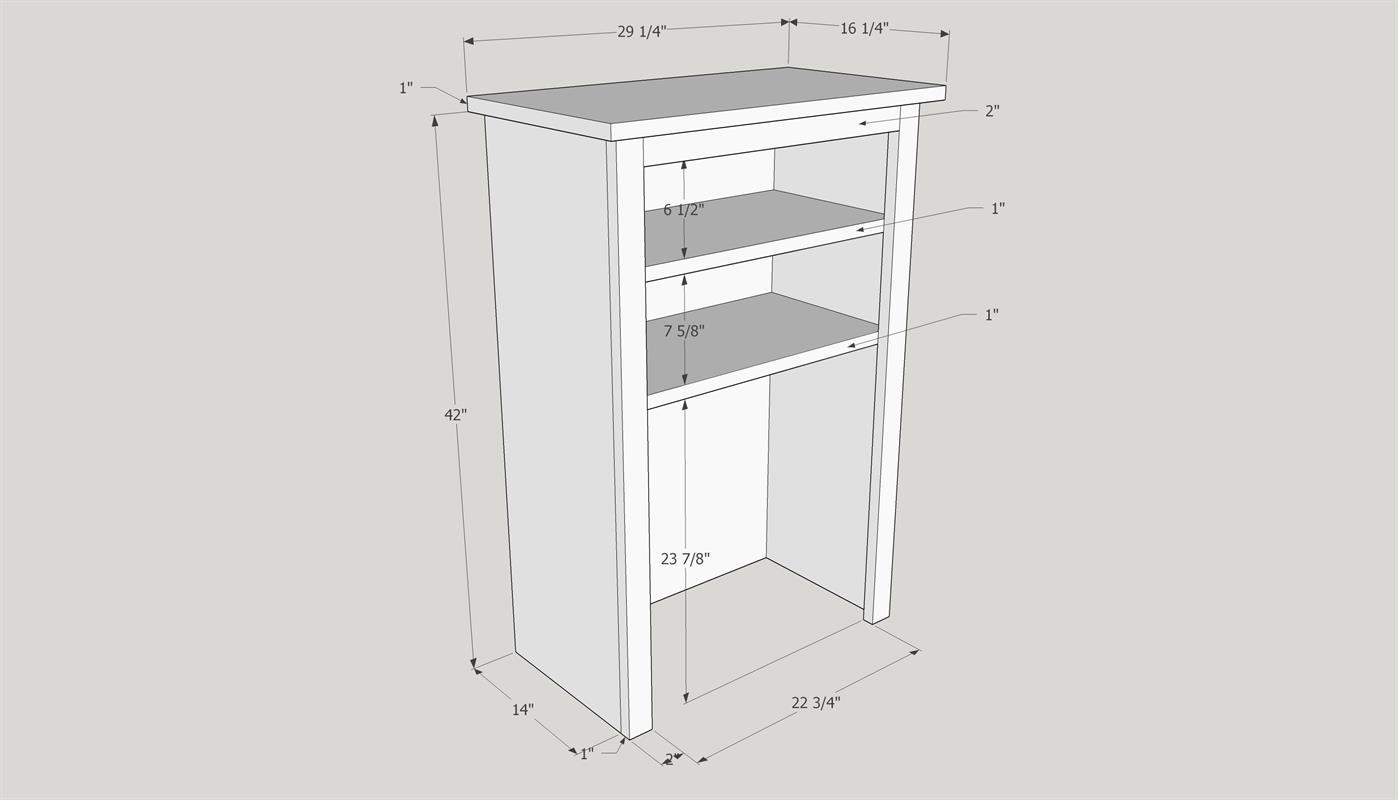

Sketch Up Hutch

Sketch Up Hutch

-

Double WOW!

Notice none of the nail holes are showing on the front of the face frames. I used like color putty and filled the holes with walnut where it was dark and used ash where it was lighter. This gives it a seamless look.

-

Load it up!

Time to load your Coffee Hutch with all your Coffee Goods!