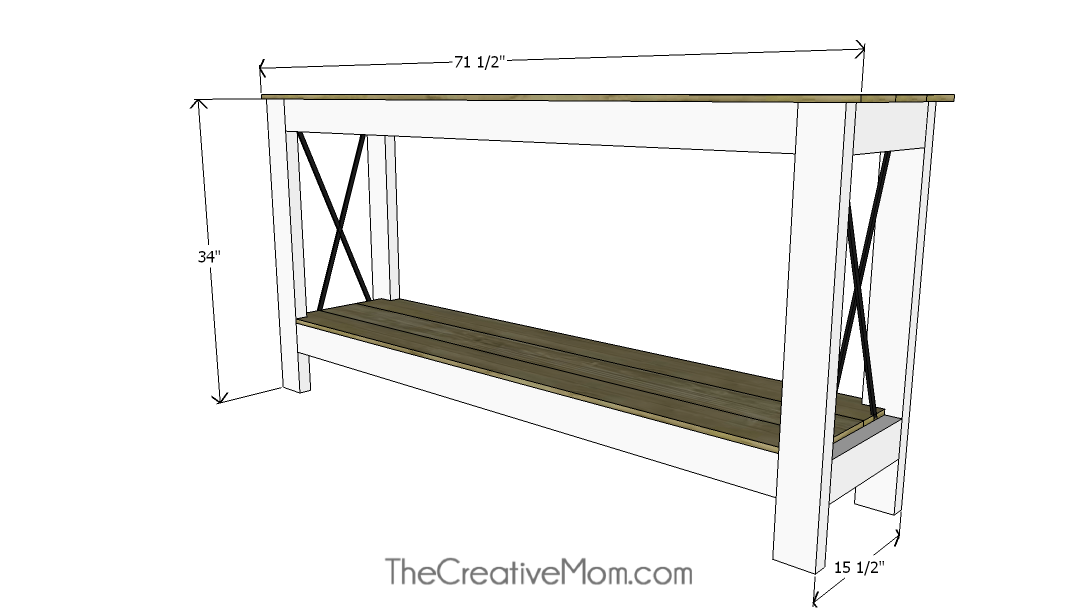

Industrial Farmhouse Console Table

By The Creative MomThis cute industrial farmhouse console table is perfect to use in an entryway, living room, dining room, or anywhere you can use a little extra table space. It is a quick and pretty easy build, using builder grade 2×4’s and a planked table top. The steel x’s are optional, but add a lot of character.

Directions

-

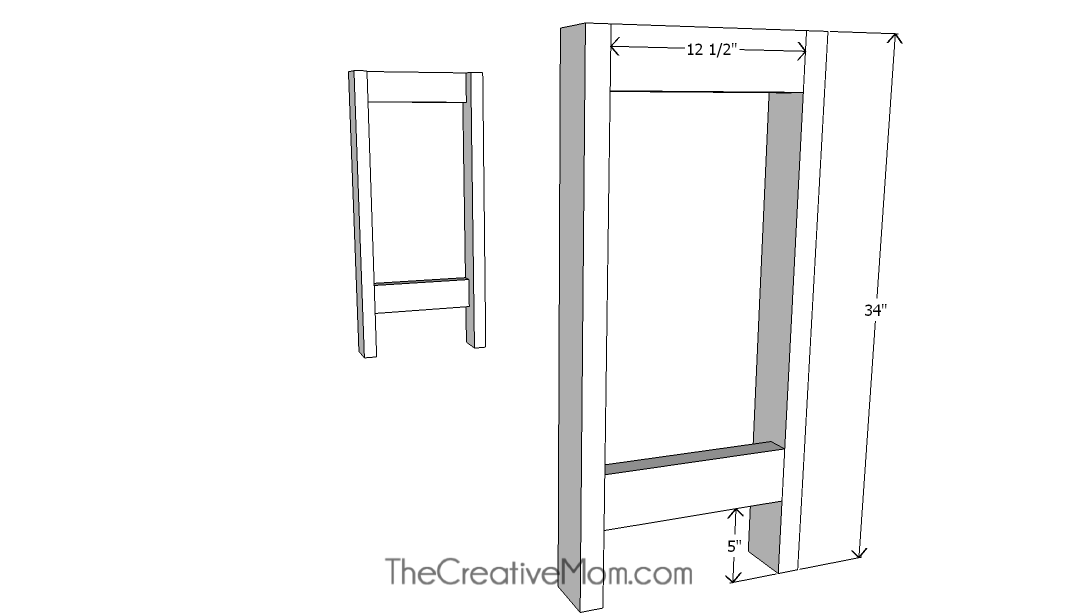

Build End Panels

Cut (4) 34" 2x4's.

.

Cut (4) 12 1/2" 2x4's. Drill 1 1/2'' pocket holes in both ends of each of the 12 1/2" boards.

.

Attach 12 1/2" 2x4's to 34" 2x4's using wood glue and 2 1/2'' pocket hole screws.

The bottom board should be 5" off the ground. -

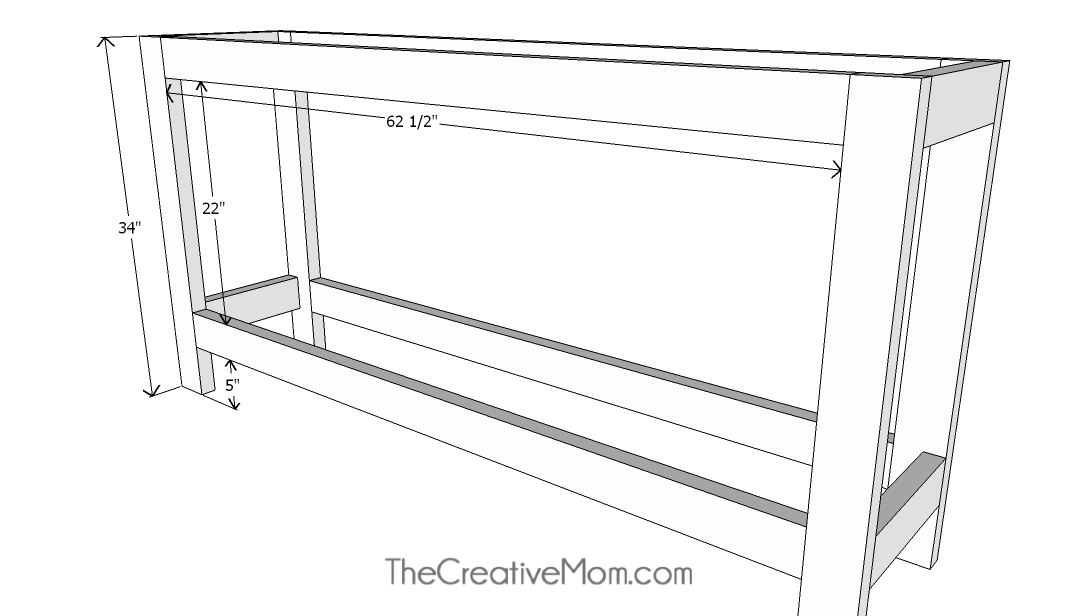

Attach Table Stretchers

Cut (4) 62 1/2" 2x4 boards. Drill 1 1/2'' pocket holes in both ends of each board.

Attach 62 1/2" 2x4's to 34" 2x4's using wood glue and 2 1/2'' pocket hole screws.

The bottom board should be 5" off the ground. -

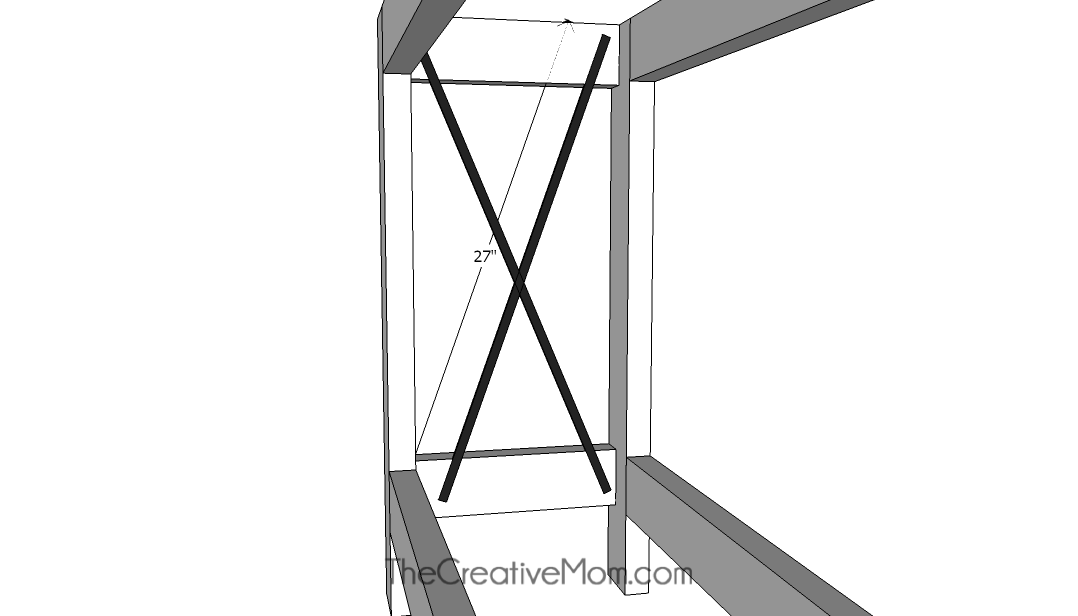

Add Metal Accents

Use a reciprocating saw with a metal blade, and cut (4) 27" flat steel bars.

Drill pilot holes in the ends of each bar.

Use 1 inch grabber screws to attach the steel bars on the inside of the ends of the table frame.

.

****note: the frame should be painted or stained before adding the metal accents**** -

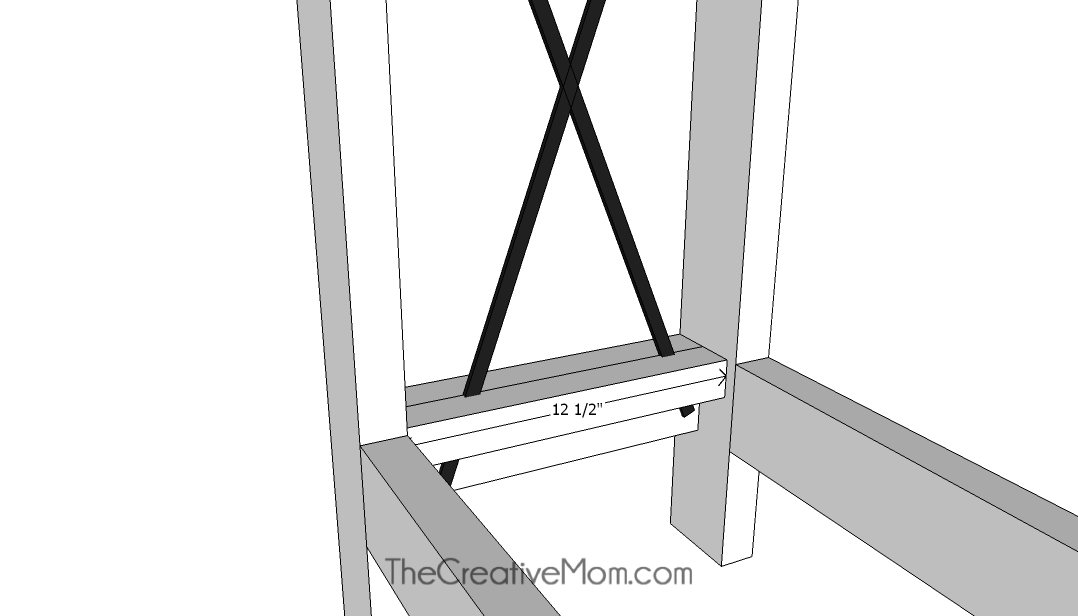

Add bottom shelf support

Cut (2) 12 1/2" 2x4's and PREPAINT (the plans show 2x2's used here. Any scrap 2x2, 2x4, or 1x2 will work.)

Drill pilot holes through the boards and attach the boards to the frame with wood glue and grabber screws. -

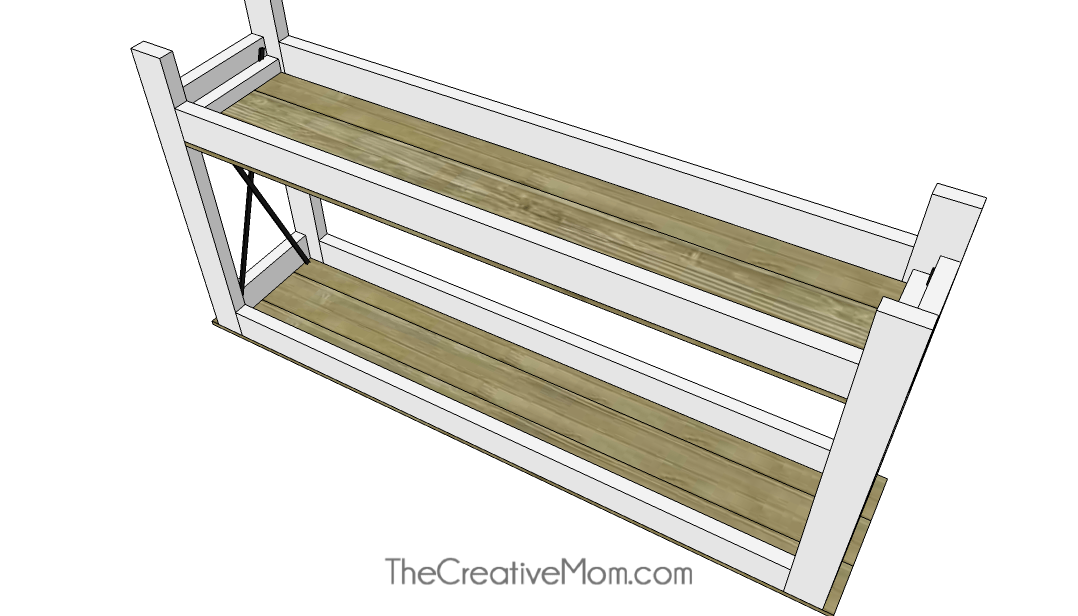

Frame is completed

This image shows the pocket holes used to build your 2x4 frame.

Once the frame is completed, before you add your metal accents, stain or paint the frame.

-

Metal Accents Attached

This photo shows the metal accents attached.

-

Shelf Support attached

This photo shows the shelf supports attached and completed.

-

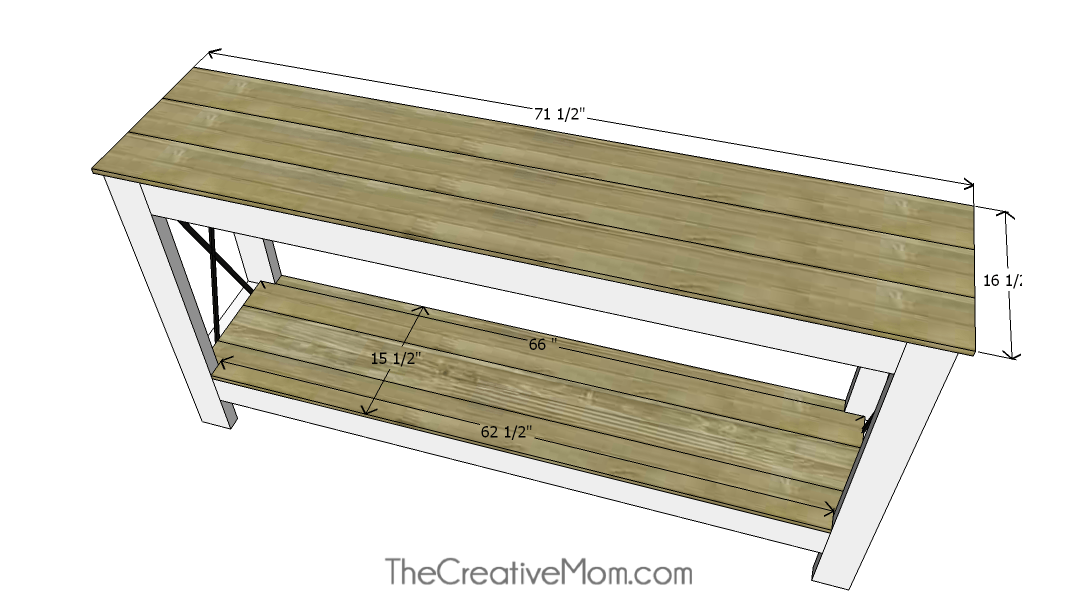

Prepare Table Top & Bottom Shelf

Prepare a table top & shelf by planking together 1x6's or 1x4's with pocket holes, glue, and screws- Or you can use a project panel found at the hardware store.

.

The table top should be 71 1/2" long by 16 1/2" wide. This would be 3 1x6's glued up.

.

The bottom shelf should be 66" long by 15 1/2" wide. This would be 3 1x6's glued up, with one 1x6 ripped to 4 1/2" wide. (see the next step for detailed cuts on the bottom shelf).

.

Once the shelves are prepared, sand and paint or stain them. -

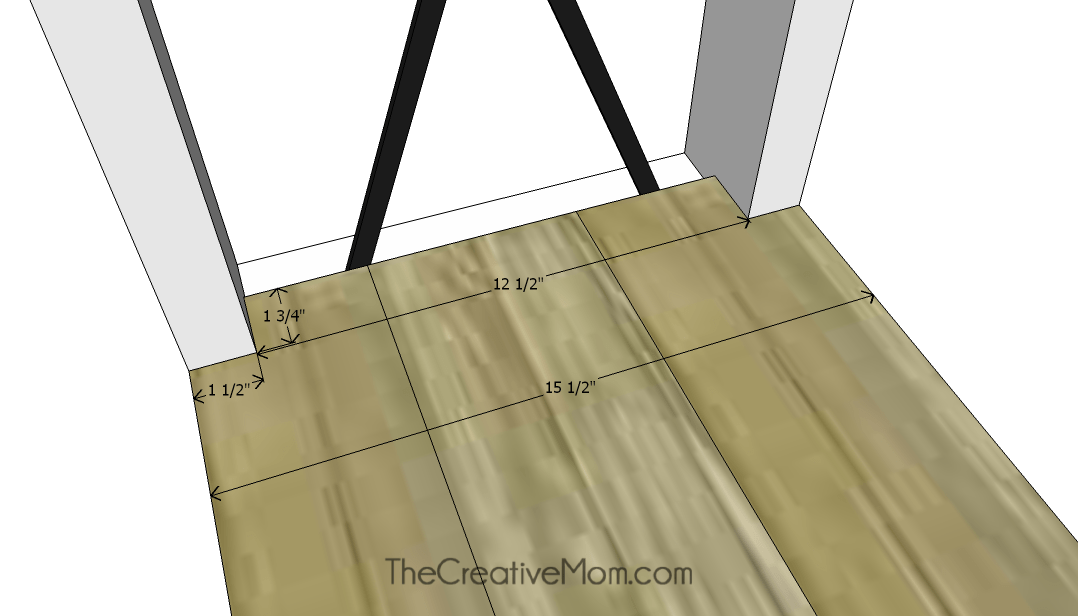

Prepare Bottom Shelf

Once you have your shelf planked, you'll need to cut notches out of each corner with a jigsaw.

See the photo for detailed cuts. You need to cut 1 1/2" x 1 3/4" on each corner. -

Attach table top

Finish the table by painting or staining. Attach the table top and shelf with 4 L-brackets each and 1/2" grabber screws.

The table top should overhang the front and each side by 1 inch. No overhang in the back, as the table is designed to sit flat against the wall. -

Table Underside

This is a photo of the underside of the table, for reference.

-

All done!

All done!