ULTIMATE Adjustable Sawhorse

By Pneumatic AddictLearn how to transform a basic, off-the-shelf, wood sawhorse into an adjustable height, multi-function workstation. The dimensions and attachments are completely customizable to match your DIY needs.

Directions

-

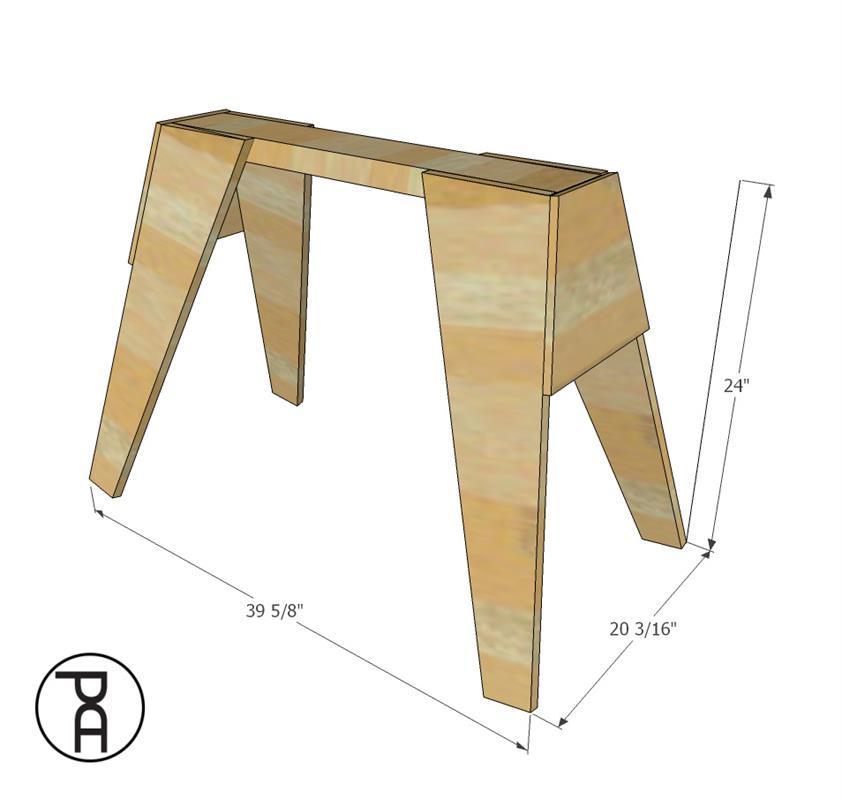

Sawhorses

Build or purchase two, 24" tall, wood sawhorses. Make sure the top plate runs horizontally.

-

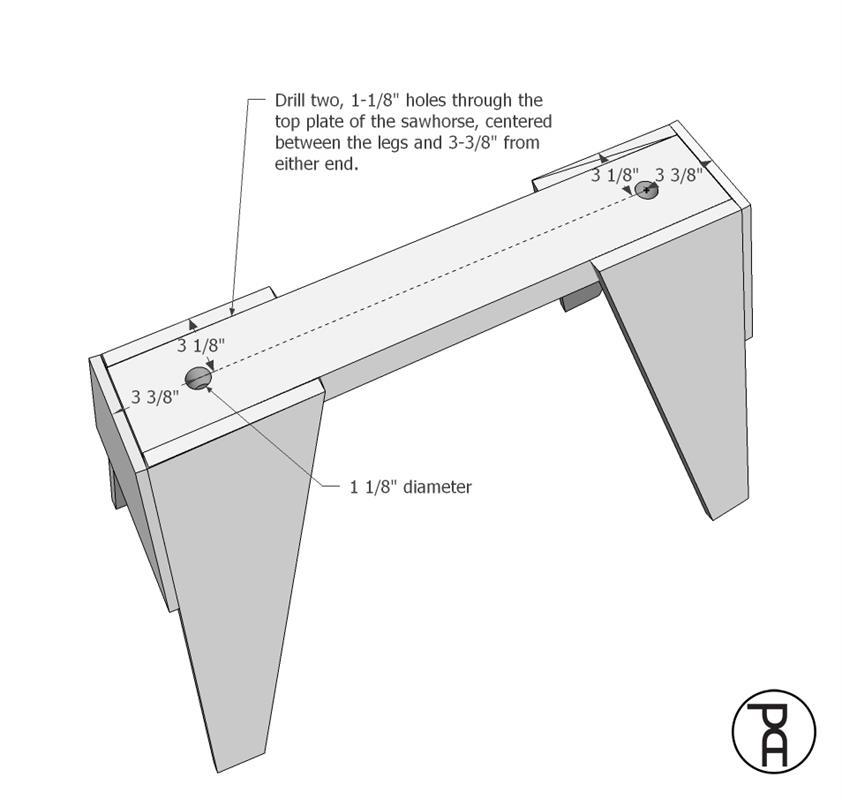

Drill Holes in Top Plate

Drill two, 1-1/8" holes through the top plate of the sawhorse, centered between the legs and 3-3/8" from either end.

-

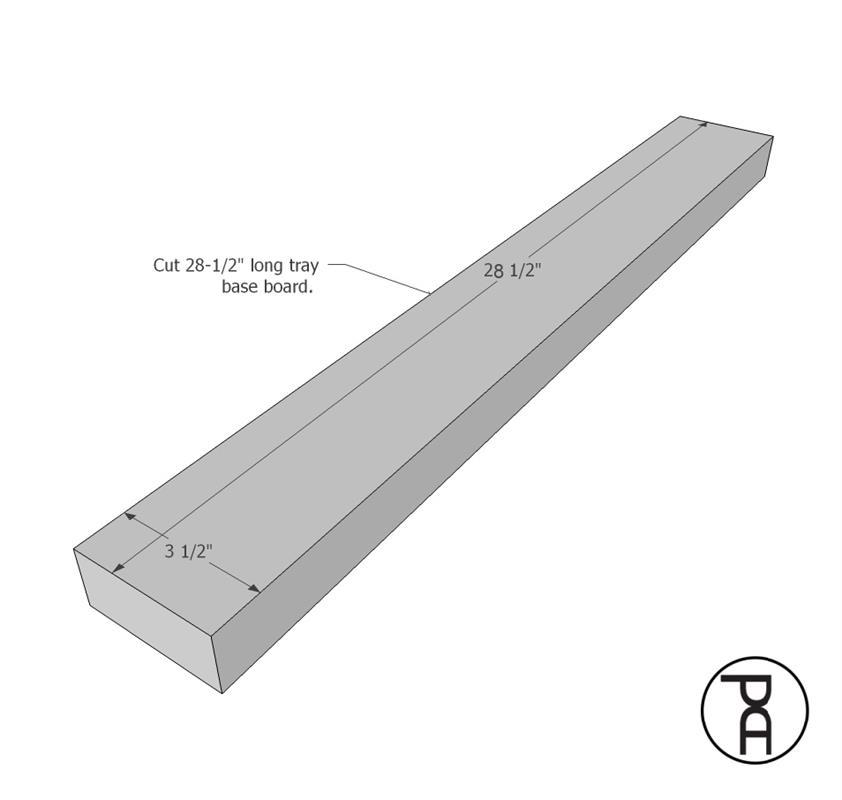

Tray Base Plate

Cut a 28-1/2" long tray base board from a 2 x 4.

-

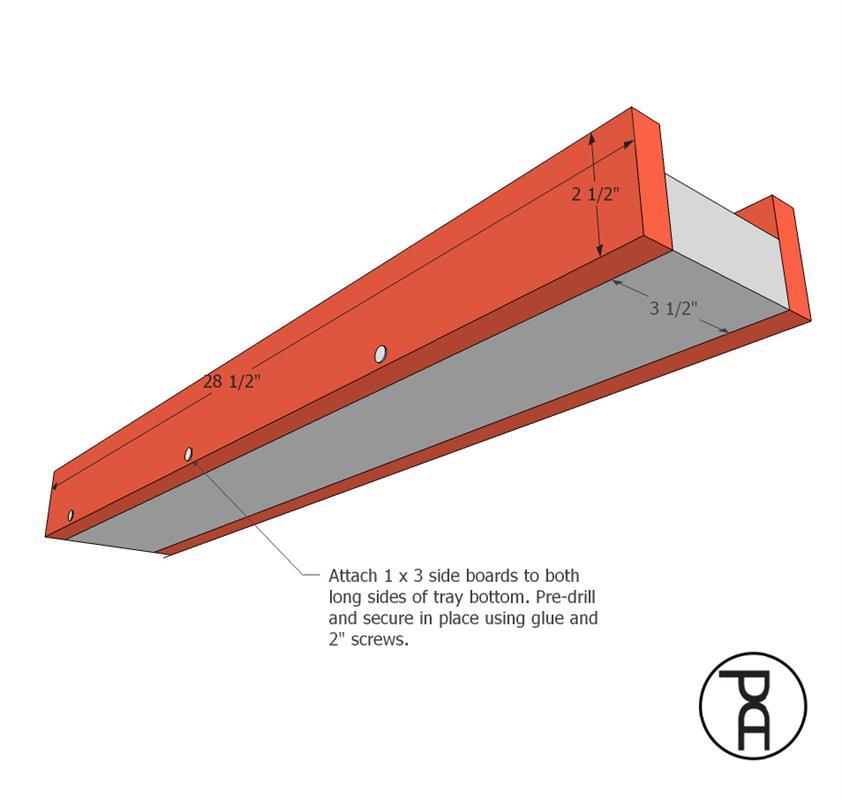

Base Sides

Attach 1 x 3 side boards to both long sides of tray bottom. Pre-drill through sides and into base. Secure in place using wood glue and 2" screws.

-

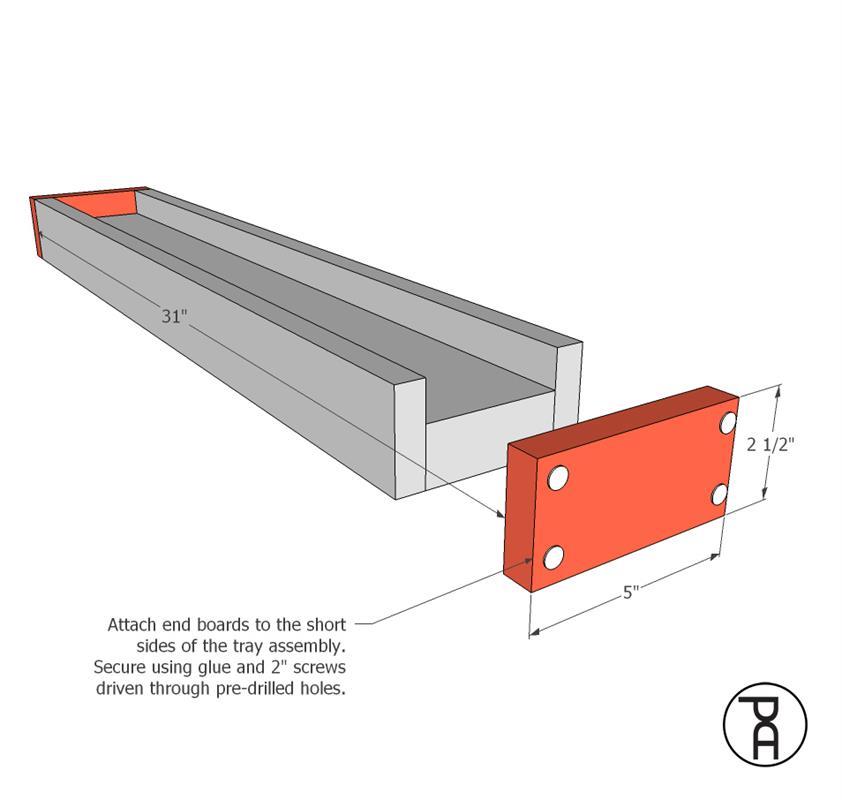

Base Ends

Attach 1 x 3 x 5" end boards to the short sides of the tray assembly. Secure in place using glue and 2" screws driven through pre-drilled holes.

-

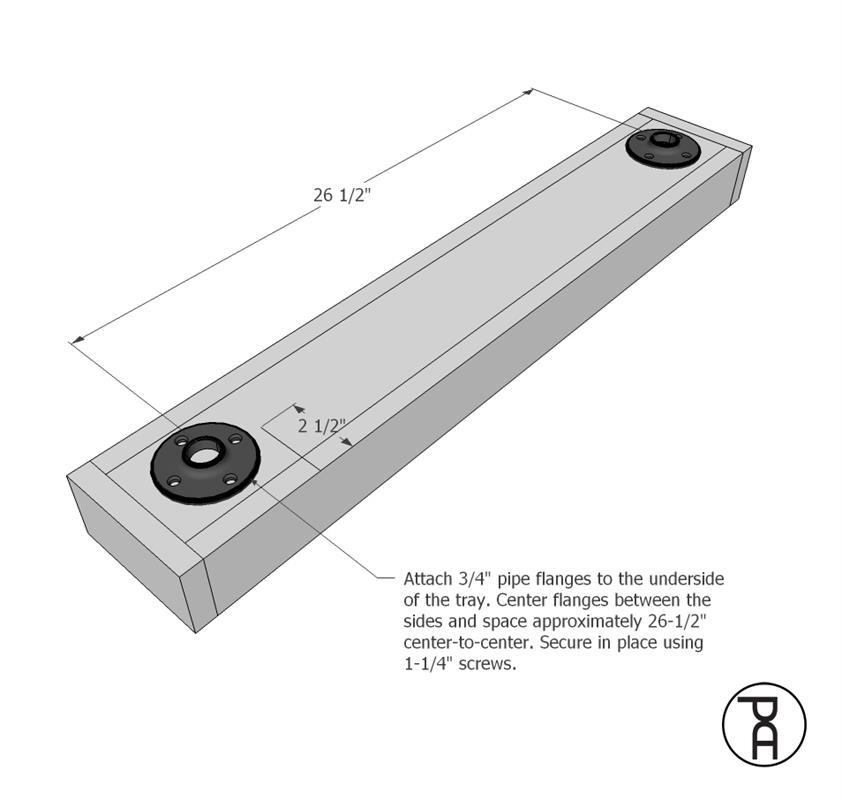

Pipe Flanges

Attach 3/4" pipe flanges to the underside of the tray. Center flanges between the sides and space approximately 26-1/2" center-to-center. Secure in place using 1-1/4" screws.

-

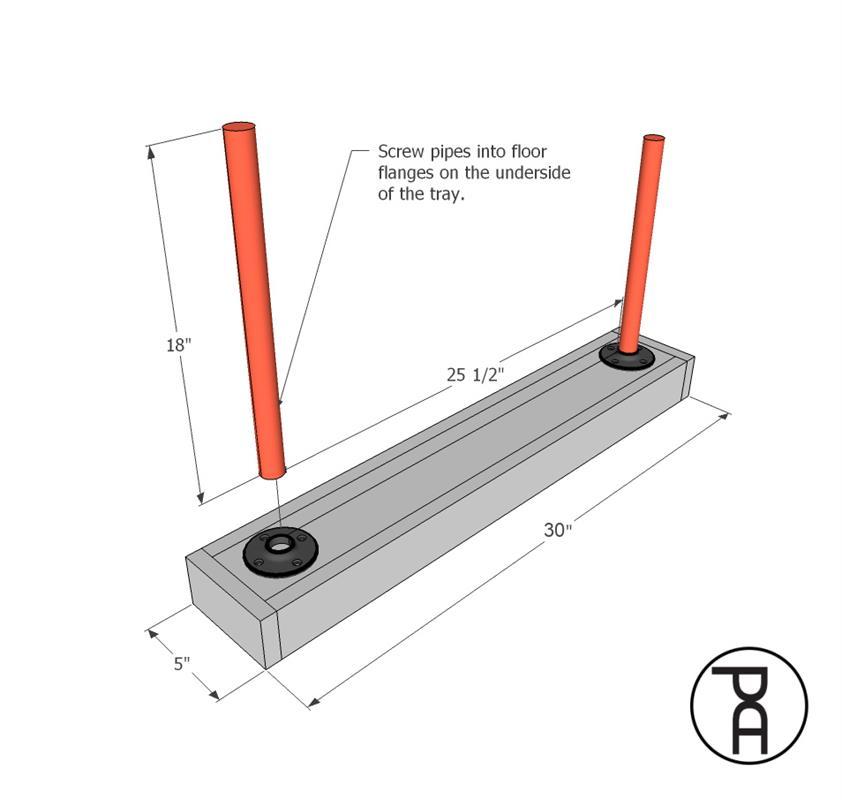

Add Pipes

Screw 3/4" x 18" pipes into the floor flanges on the underside of the tray.

-

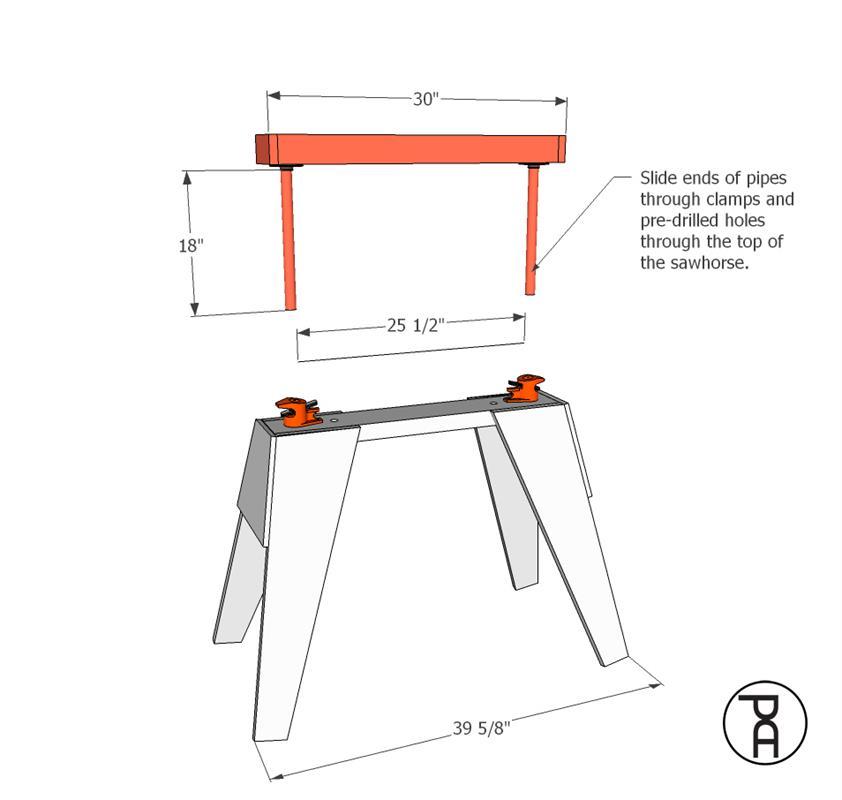

Insert Tray

Place the sliding ends of the pipe clamps over the holes drilled in the sawhorse top plate, levers facing inward. Slide ends of pipes through the openings in the clamps through the top of the sawhorse.

-

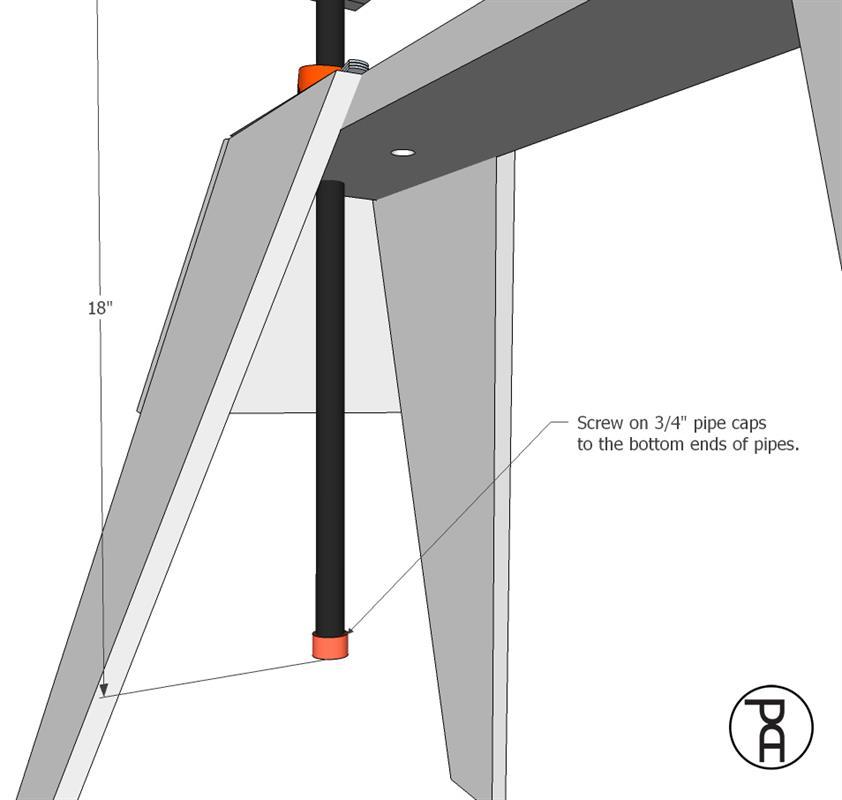

Pipe Caps

Screw on 3/4" pipe caps to the bottom ends of the 18" pipes.

-

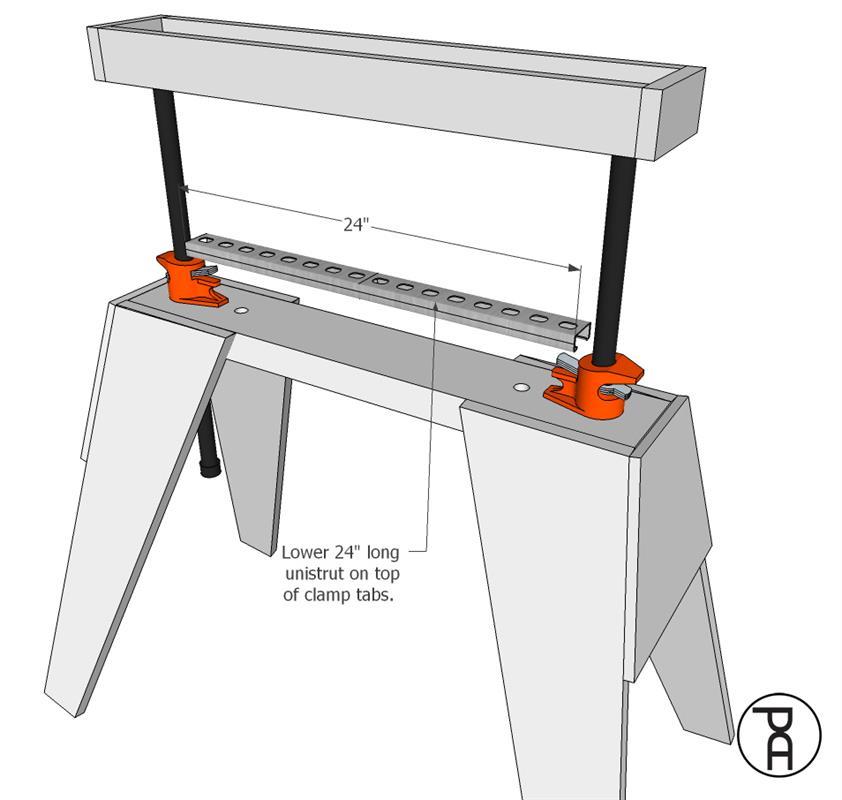

Place Unistrut

Place 24" steel Unistrut on top of the pipe clamp tabs, making sure the ends engage both clamps and allow the pipes to slide.

-

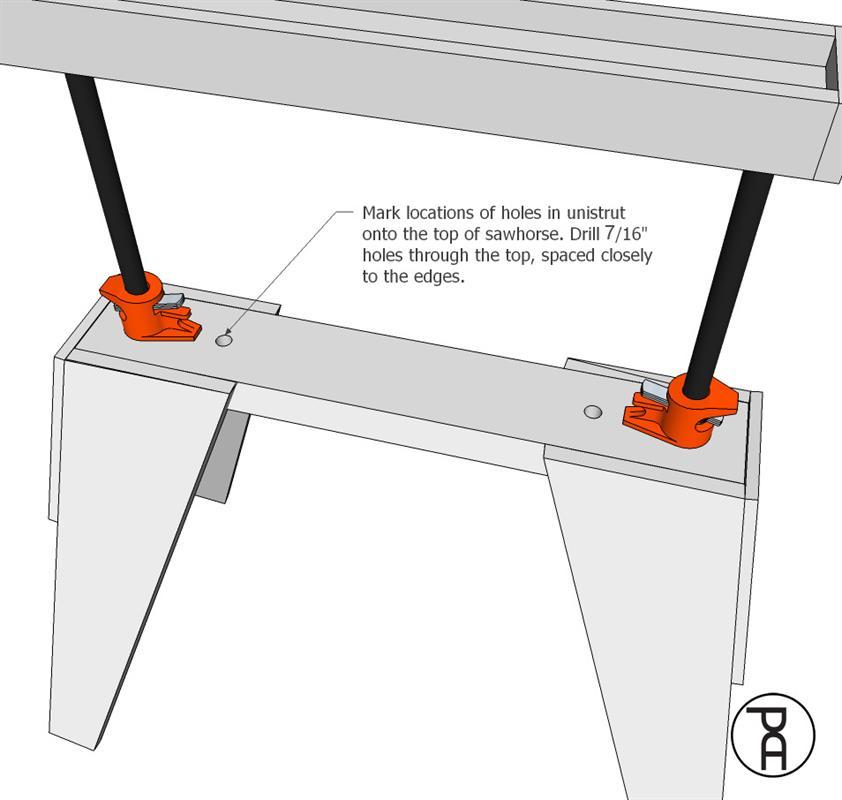

Rope Holes

Mark locations of holes in Unistrut onto the top of sawhorse. Drill 5/16" holes through the top, spaced closely to the edges.

-

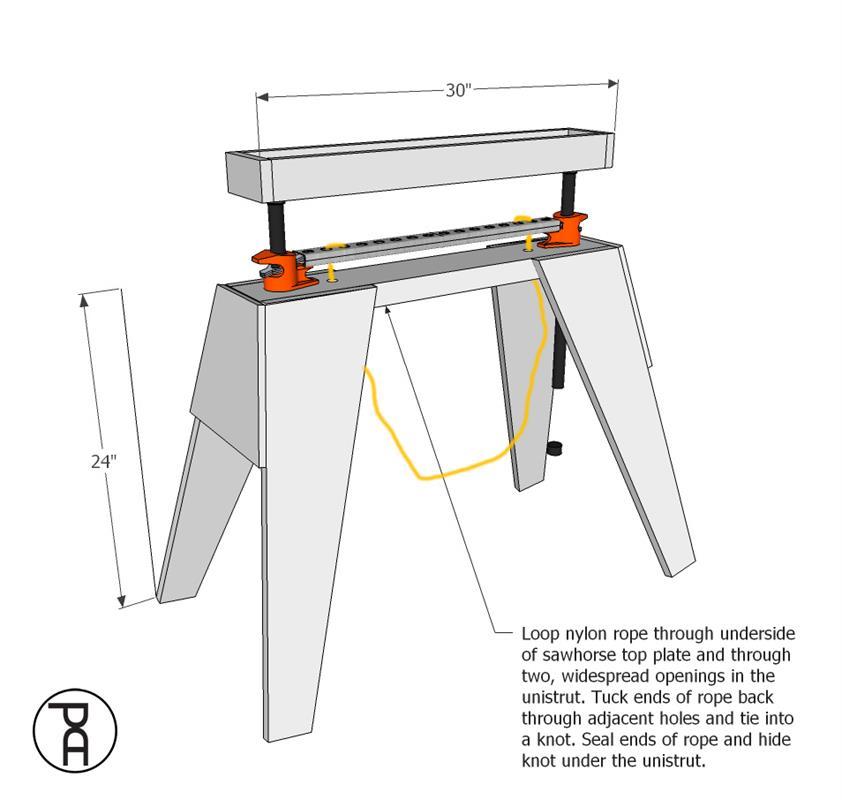

Add Rope

Loop a length of nylon rope through underside of sawhorse top plate and through two, widespread openings in the Unistrut. Adjust the length of the loop to be comfortable to pull down with your foot. Tuck the ends of rope back through adjacent holes and tie them into a knot. Seal the ends of rope and hide knot under the Unistrut.

-

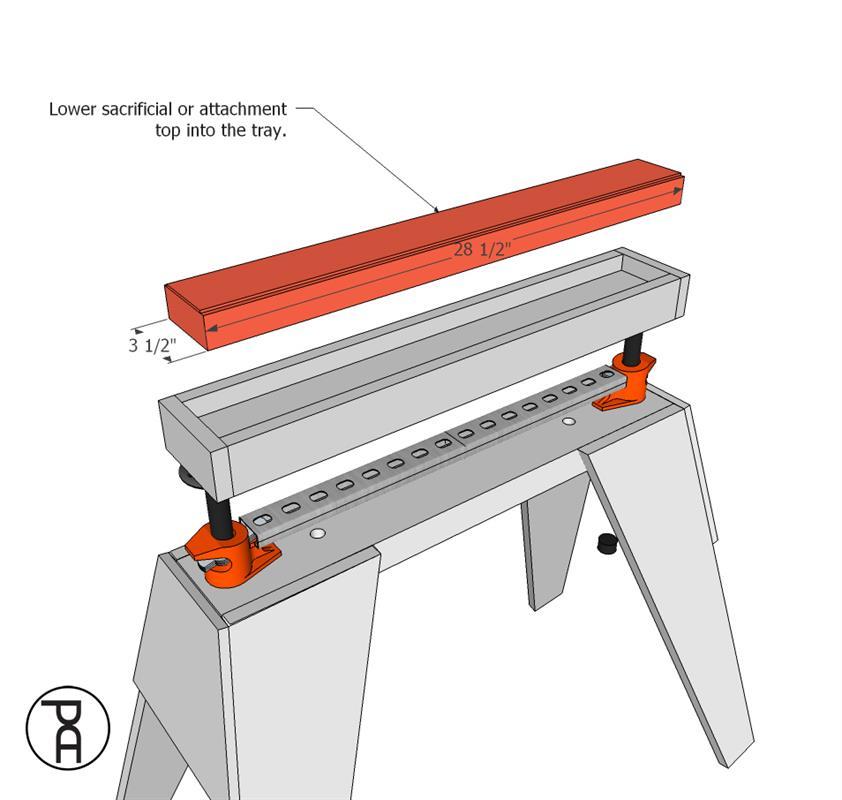

Add Sacrificial Board

Lower 2 x 4 x 28-1/2" sacrificial board or attachment top into the tray.

-

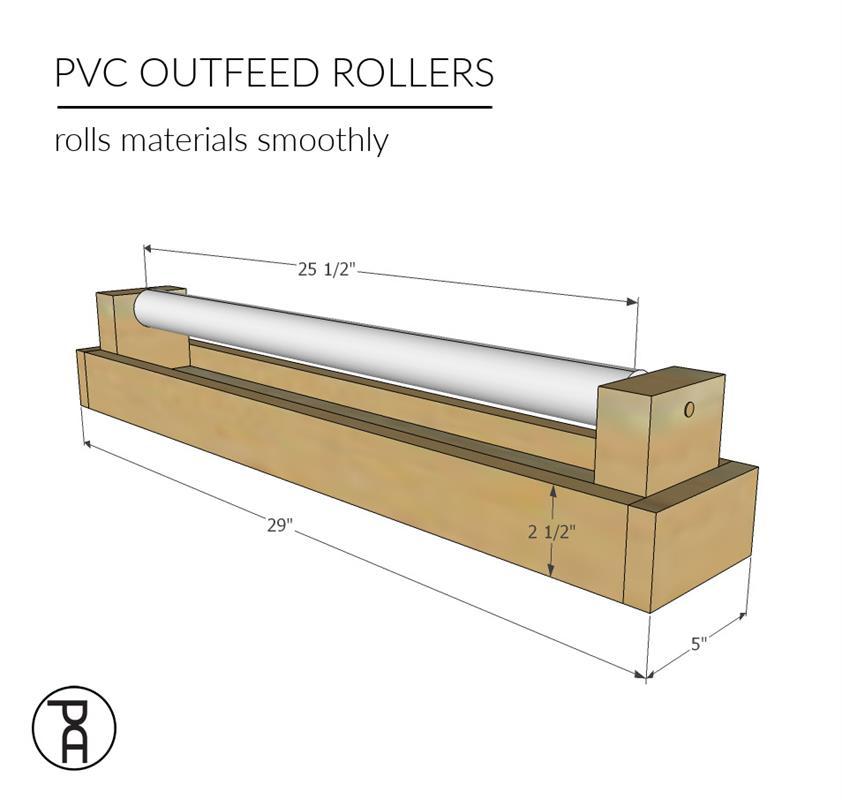

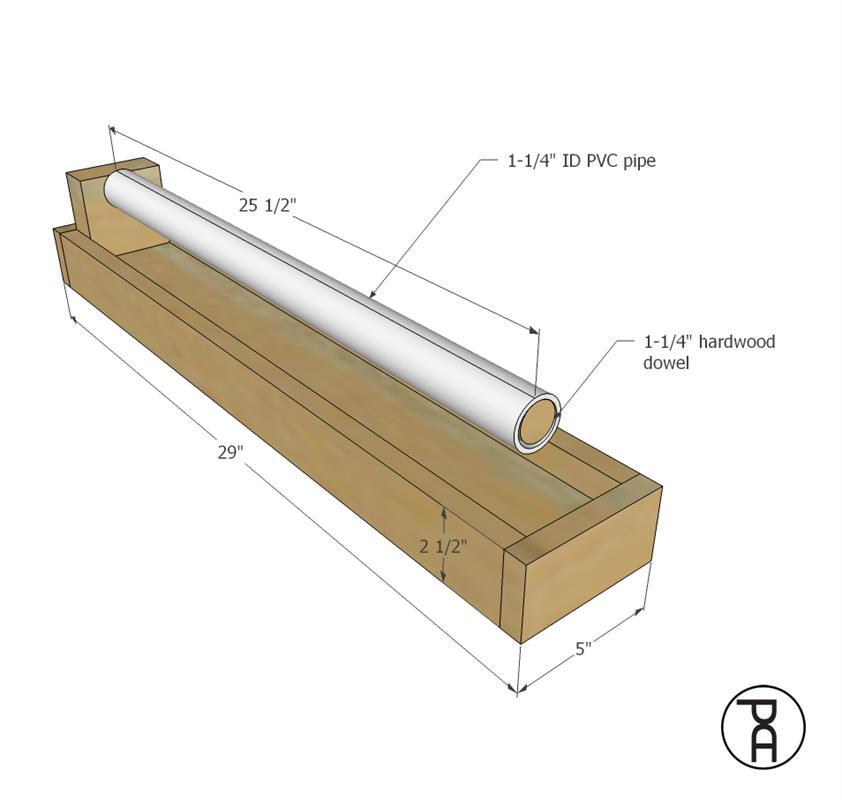

Optional: Outfeed Roller

Create a 3-1/2" x 28-1/2" hardwood and PVC roller.

-

Roller

Using a dense hardwood dowel, like oak will allow the PVC to roll easily and won't wear out quickly.

-

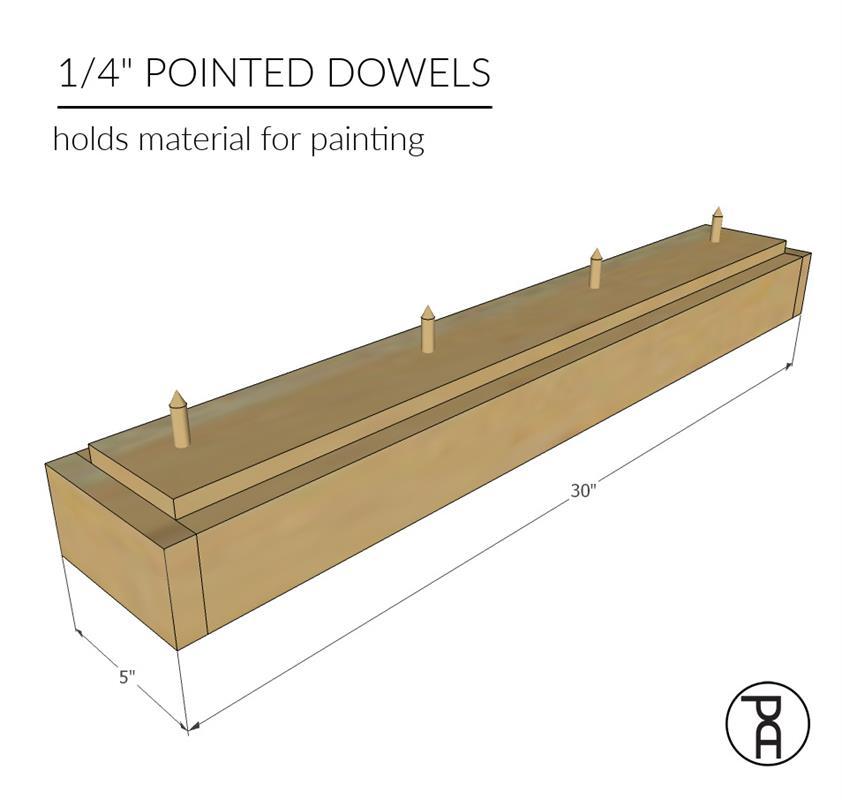

Optional: Pointed Dowels

Build a 3-1/2" x 28-1/2" insert with 1/4" pointed, sharpened dowels, glued into a base board. The pointed dowels work well to support a freshly painted surface.

-

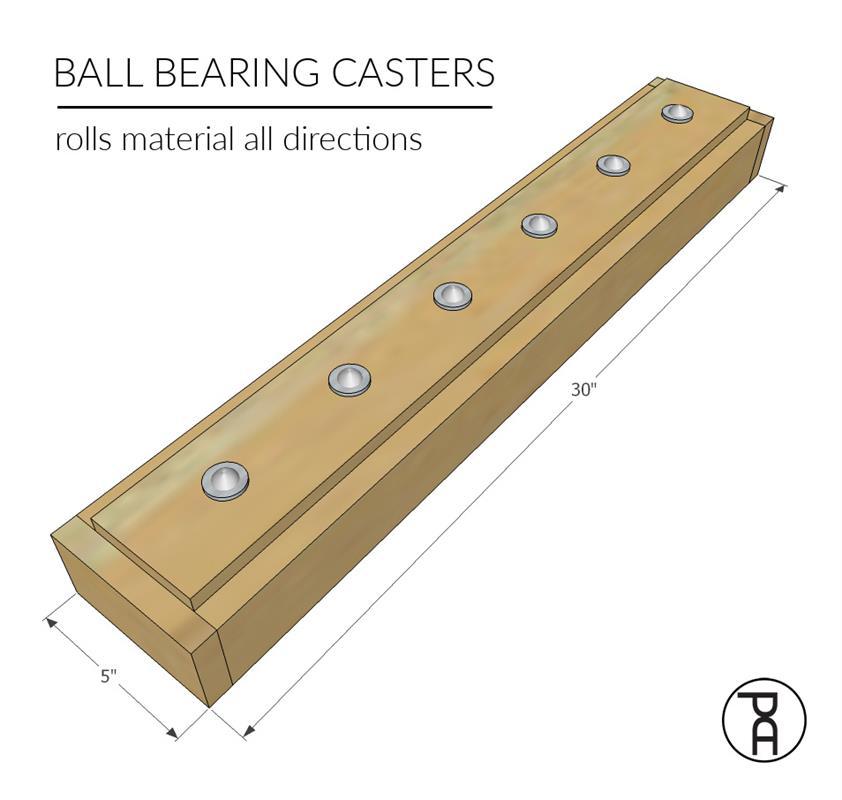

Optional: Ball Bearing Casters

Build a 3-1/2" x 28-1/2" insert and attach inset ball bearing casters. Ball bearing casters spin in all directions and are good to moving large or heavy materials.

-

Get More Ideas

Check out the Pneumatic Addict channel on YouTube and visit PneumaticAddict.com for more free project plans and DIY ideas.