DIY Workbench – Metric

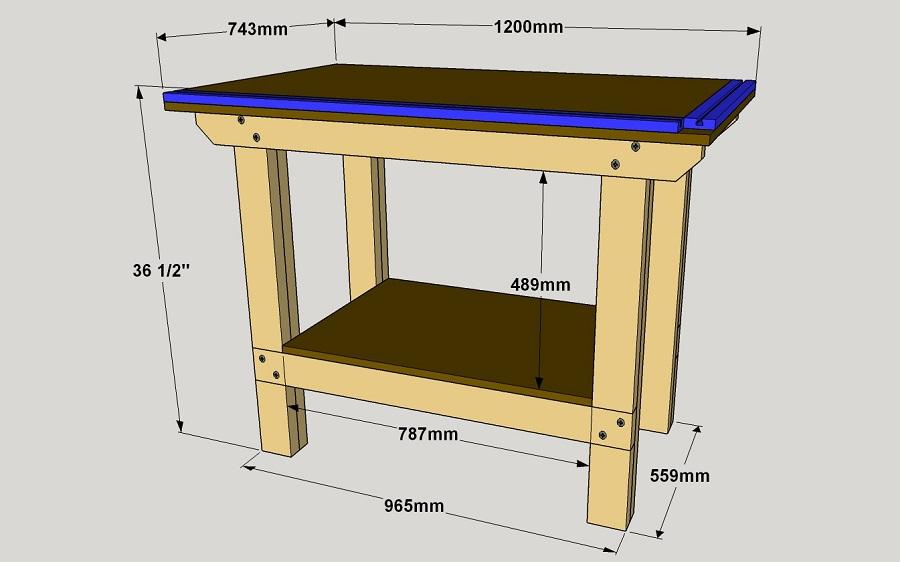

By Kreg ToolThis workbench is easy to build, but built to withstand heavy use. Plus, it offers a versatile benchtop, thanks to a Universal Clamp Trak Kit from Kreg that’s mounted along the front and one end. Combined with a couple of Kreg Bench Clamps, this makes a slick setup for holding pieces while you work.

Directions

-

Cut Leg Parts

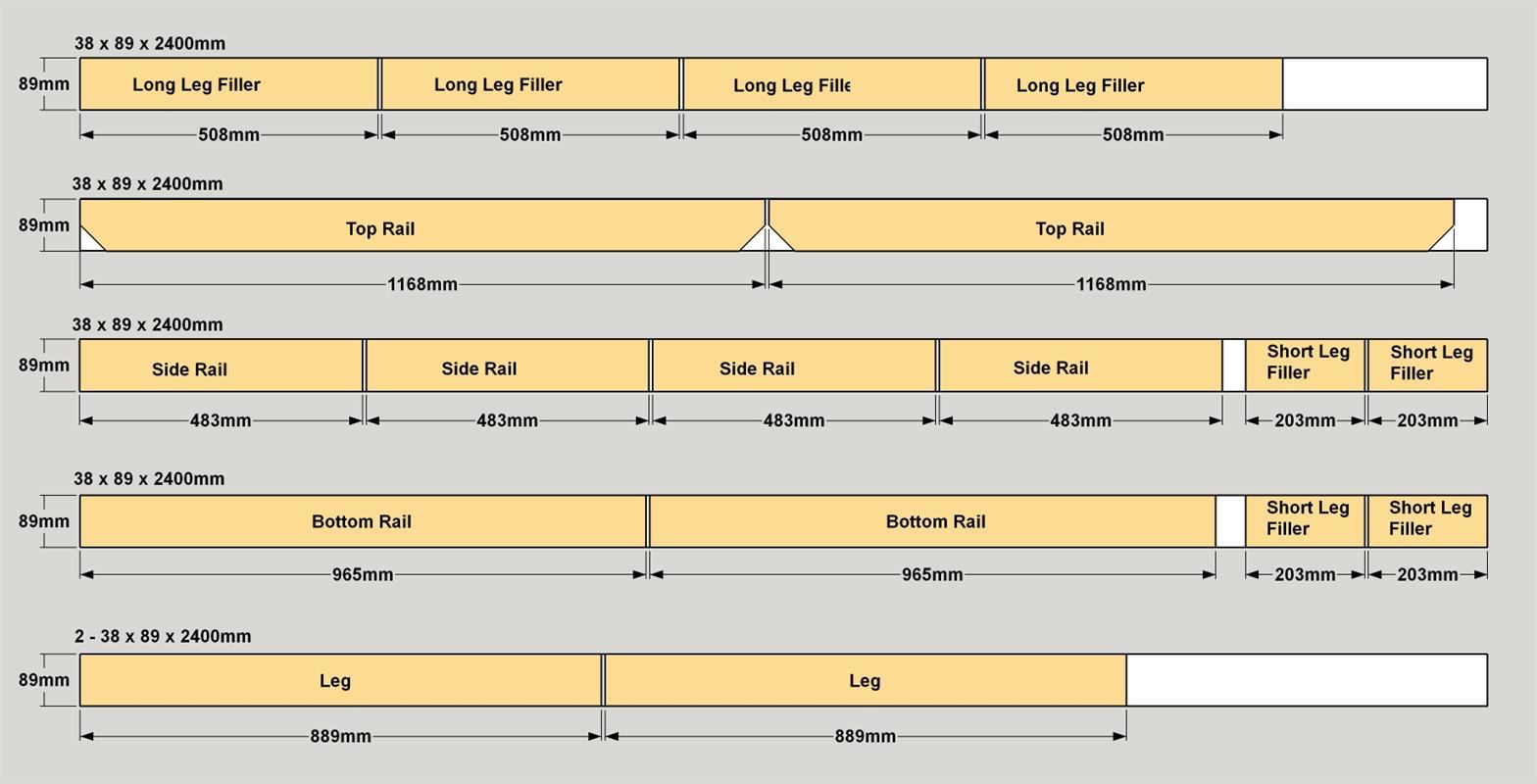

Cut four Legs, and four Short Leg Fillers, and four Long Leg Fillers to length from 38x89mm boards, as shown in the cutting diagram. Sand the parts smooth.

Tip: Be Picky when Picking Boards

The base for this bench is made from 38x89mm stud lumber. These boards are inexpensive, sturdy, and easy to cut. They’re not always pretty, though. When you’re buying lumber, take your time and find boards that are straight, clean, and that don’t have torn up edges. Even if you have to spend a while digging for boards, it will take a lot less time than you’d spend sanding and trying to make bad boards look good. Plus, you’ll have an easier time building, and you’ll end up with a better-looking bench.

-

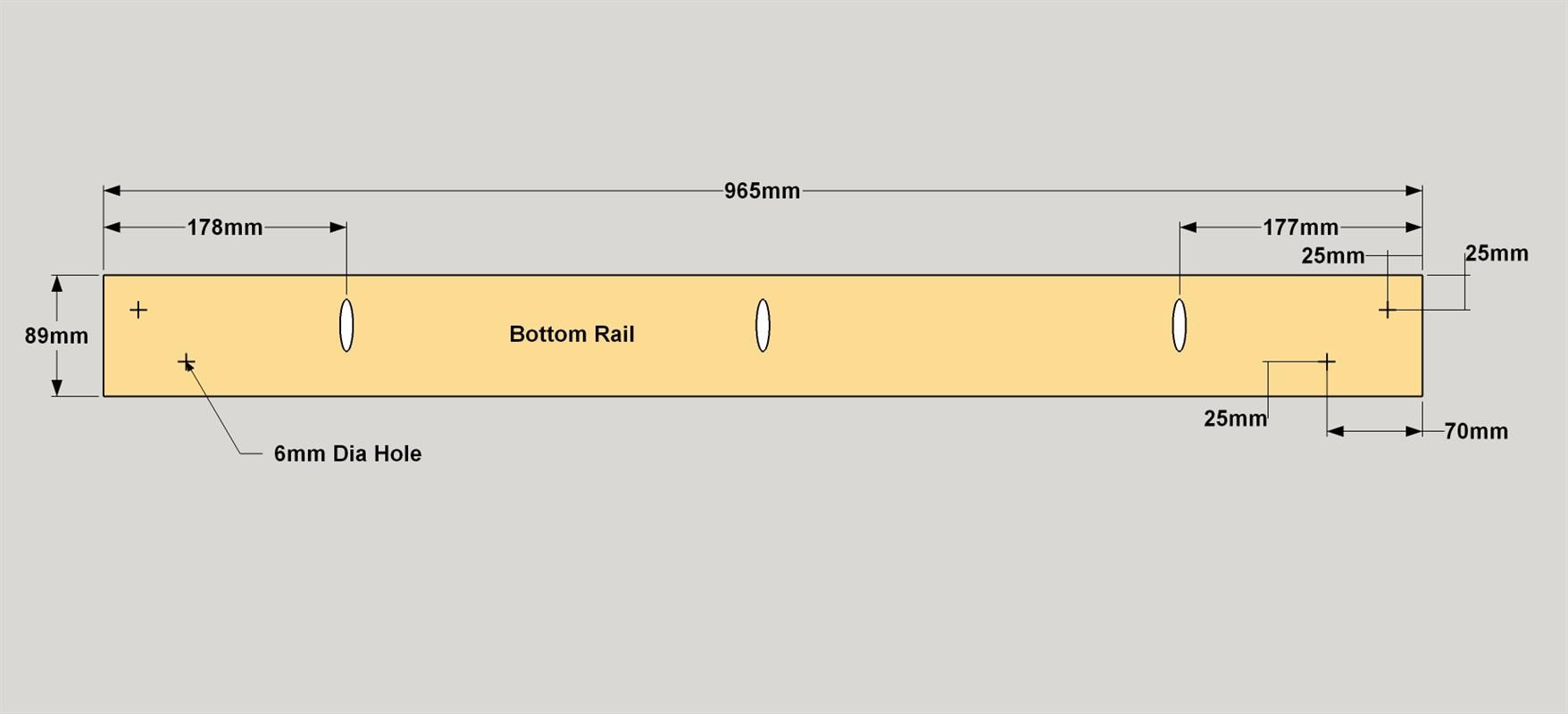

Make the Bottom Rails

Cut two Bottom Rails to length from 38x89mm boards, as shown in the cutting diagram. Drill 6mm-diameter holes where shown. Then, with your pocket-hole jig set up for 19mm material, drill pocket holes along one edge of each Bottom Rail. Sand the Bottom Rails smooth.

-

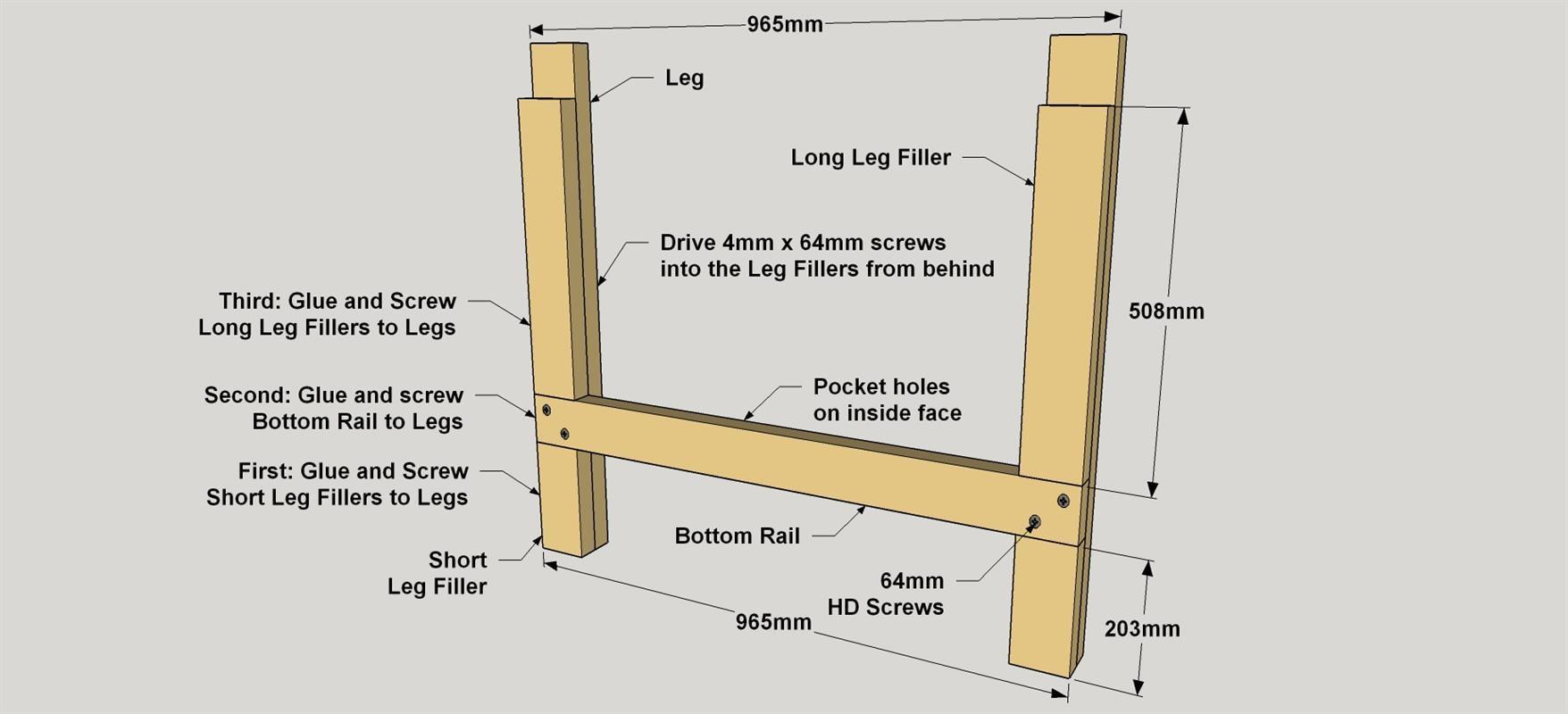

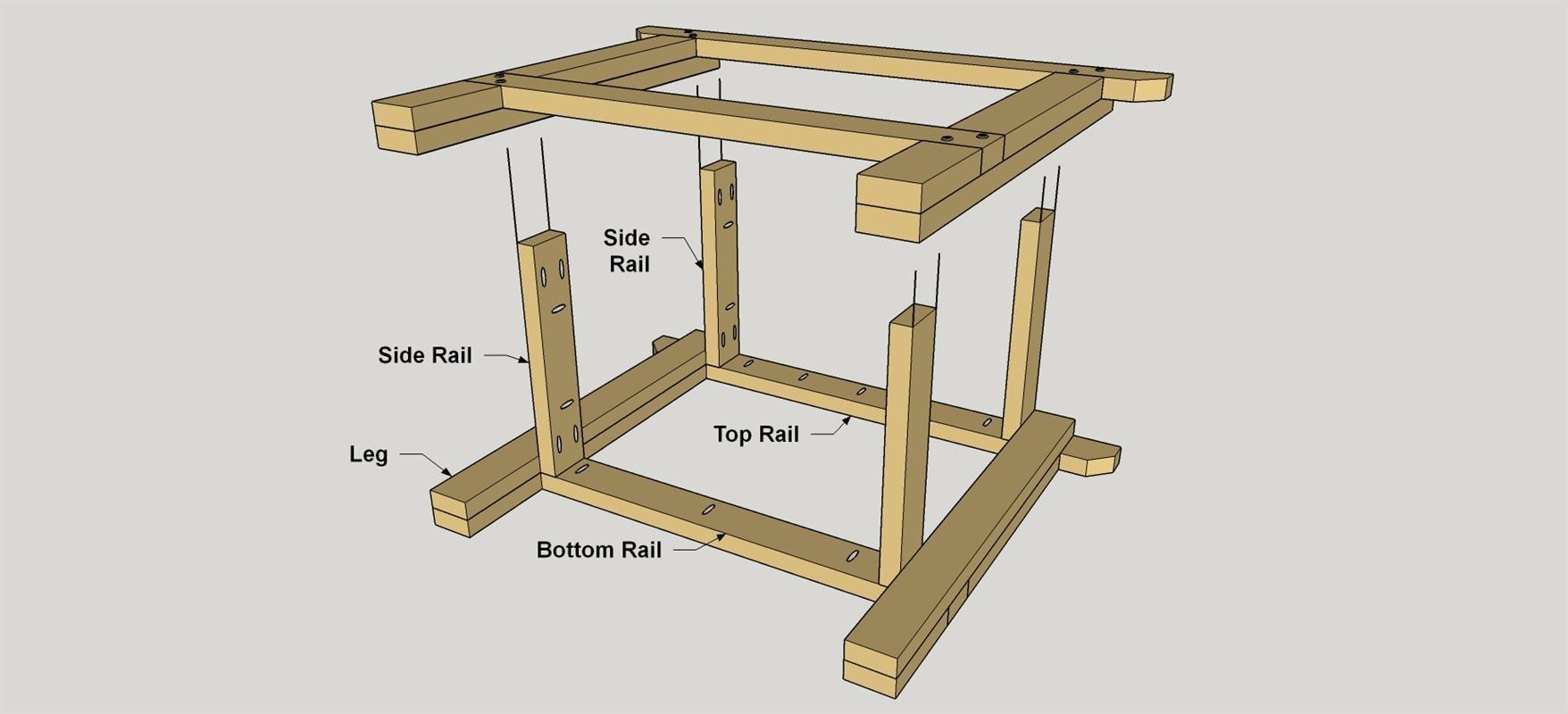

Create Leg Assemblies

Spread glue on the back face of each Short Leg Filler, and then clamp them to the Legs so they are flush on the sides and one end. Secure each Short Leg Filler to the Leg from behind using four 64mm flathead wood screws. You shouldn’t even need to drill pilot holes. Next, position the Bottom Rail so it’s resting on the Short Leg Fillers, and clamp it in place. Make sure the distance between the leg assemblies is correct, and attach the Bottom Rail with large screws. We used Kreg HD Screws. Now you can add the Long Leg Fillers in the same way as you added the short ones, attaching each one with six 65mm flathead wood screws.

-

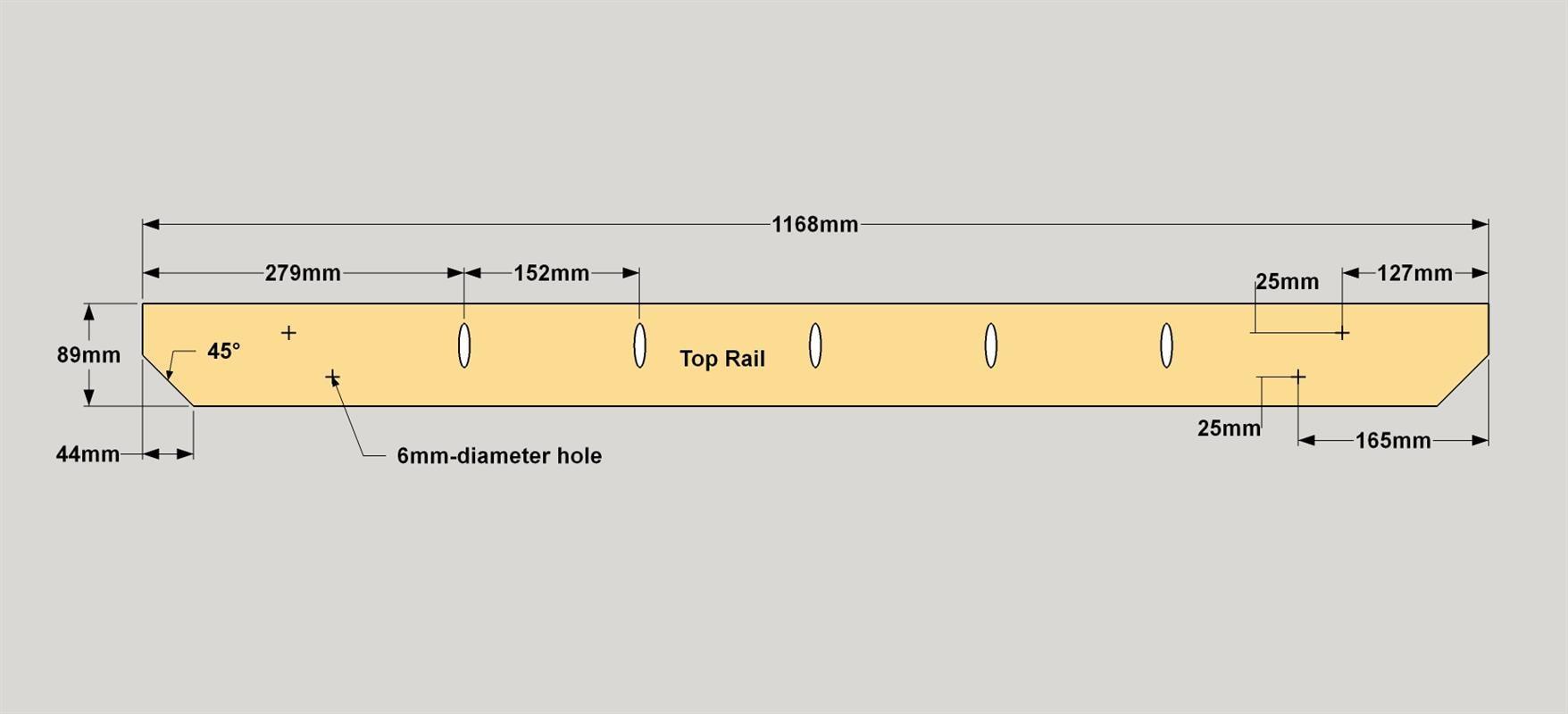

Make the Top Rails

Cut two Top Rails to length, as shown in the cutting Diagram. Trim off the corners, as shown. Next, drill 6mm-diameter holes at the location shown. Then, with your pocket-hole jig set up for 19mm material, drill pocket holes along the long edge of each Top Rail. Sand the Top Rails smooth.

-

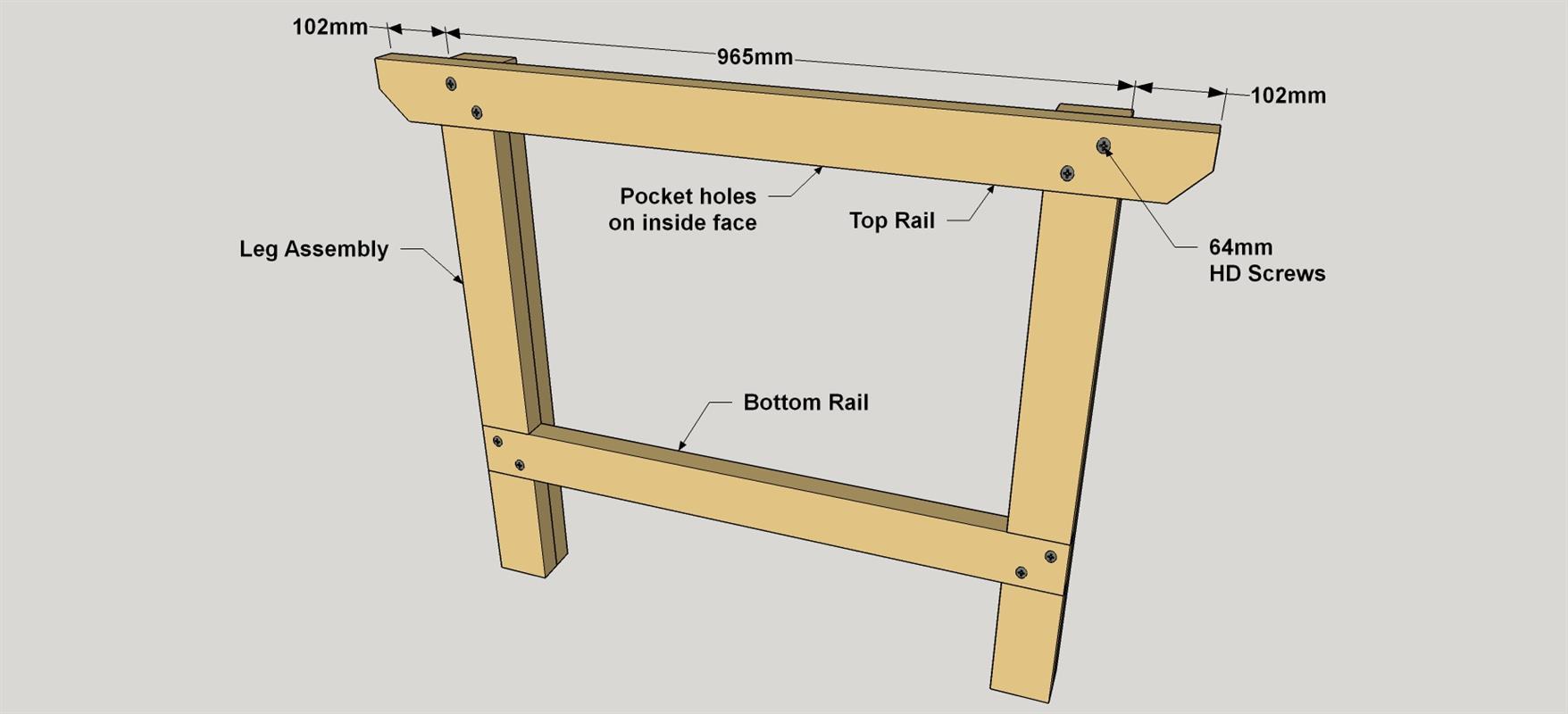

Attach the Top Rails

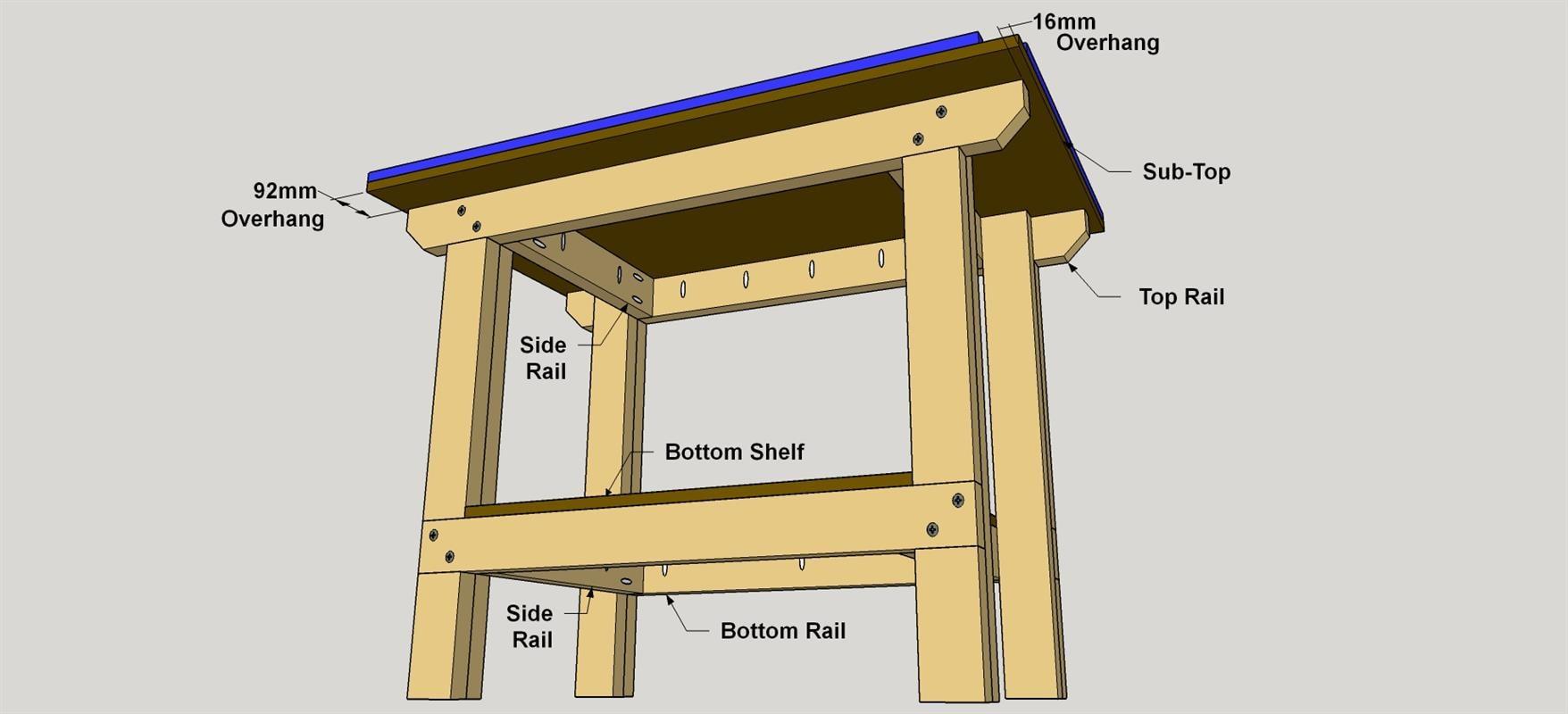

Glue and clamp the Top Rail to the leg assemblies as shown. Make sure that the bench legs are parallel and that the distance between them is correct, and then secure each Top Rail to the Legs with four HD Screws.

-

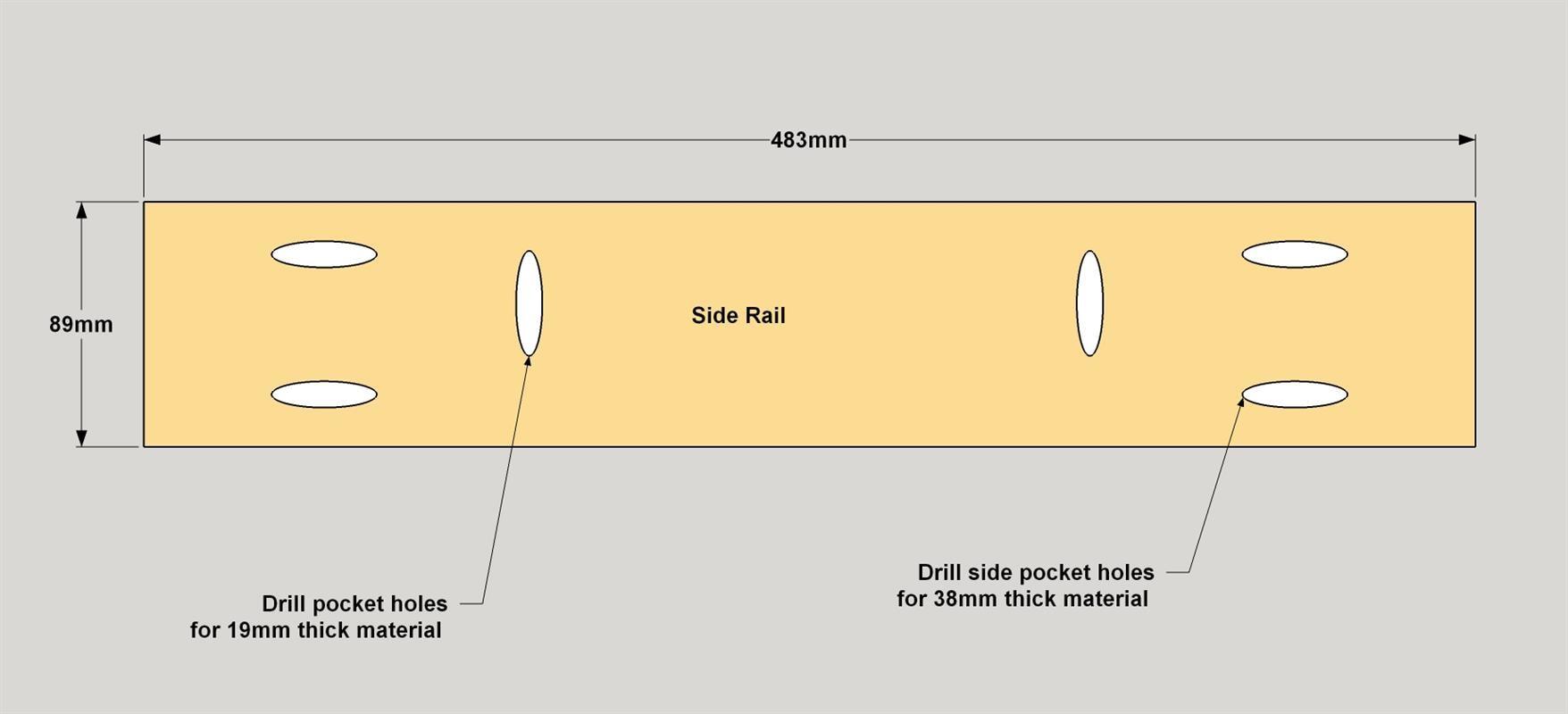

Make the Side Rails

Cut four Side Rails to length, as shown in the cutting diagram. Then you can drill pocket holes in the Side Rails where shown. This requires two pocket-hole jig setups. For the pocket holes along the edge (which will be used to attach the shelf later), drill the holes with your jig set up for 19mm material. Then switch your jig (and bit) setup to 38mm material, and drill pocket holes in the ends of each Side Rail. Sand the parts smooth after you drill the pocket holes

-

Attach the Side Rails

Attach the side rails to one of the leg/rail assemblies by driving 64mm coarse-thread pocket-hole screws into the Top Rail and Bottom Rail, as shown. Then attach the other leg/rail assembly.

-

Make the Top and Shelf

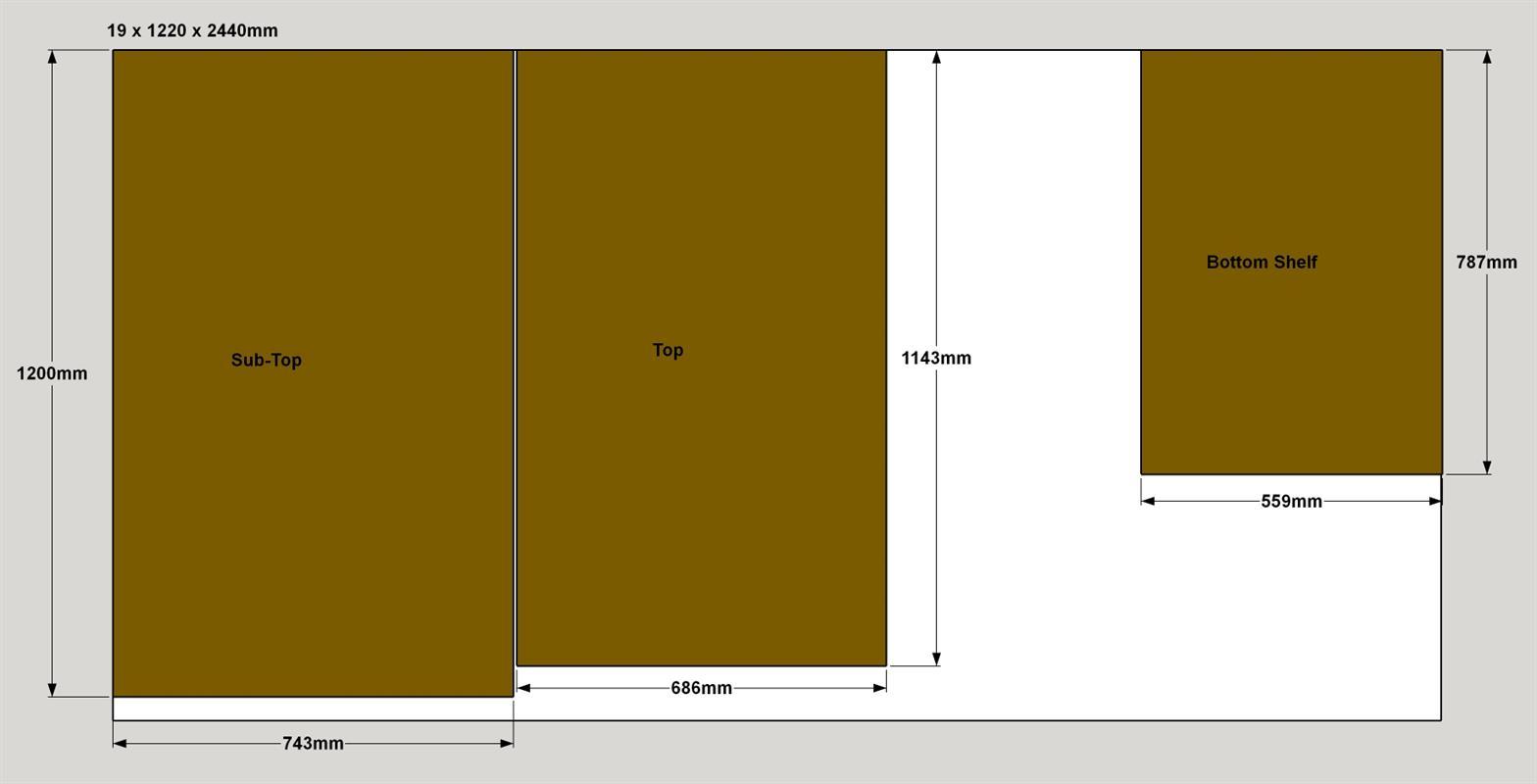

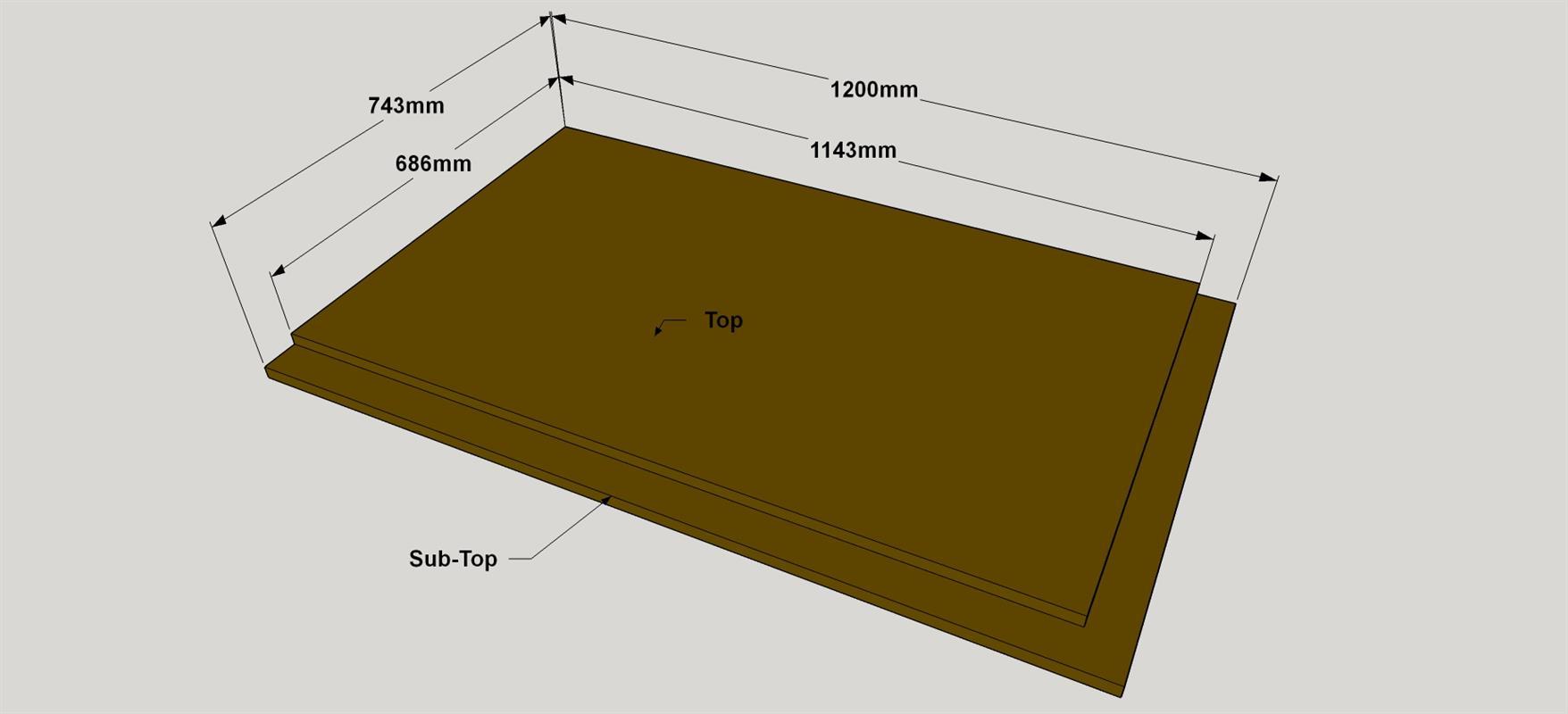

From a sheet of 19mm MDF, cut out one Top, one Sub-Top, and one Bottom Shelf to size, as shown in the cutting diagram. The dimensions shown accommodate the Kreg Universal Clamp Trak Kit we installed. If you’re not going to add this feature, make both top layers the size shown for the Sub-Top.

Tip: Learn to Work with MDF

MDF (medium density fiberboard) is a great material for making a workbench. It’s dense, durable, and very flat. MDF does present a few challenges, though. First, the sheets are big and they’re heavy. You may want to have the home center crosscut the sheet into two pieces—making the cut at about 1500mm from one end—to make it easier to haul home. Or, for a small fee, you can have them cut the parts from the sheet at the sizes needed. When you cut MDF, it produces a lot of fine dust. Wear a dust mask while you cut to prevent breathing the dust in.

-

Assemble the Top

Spread glue on the underside of the Top, and then glue it to the Sub-Top keeping one edge and one end flush, as shown. Clamp the parts together while the glue sets, or drive a few 32mm screws in from the underside instead of using clamps.

-

Add the Track

Once the glue is set on the bench top assembly, install the Kreg Clamp Trak Kit to the Sub-Top following the manufacturer’s instructions.

-

Add the Top and Shelf, then Finish

Install the bench top assembly by first positioning it, and then checking for equal overhangs at the front and back, and on each end, as shown. Then attach the top assembly using 32mm coarse-thread pocket-hole screws. Install the Bottom Shelf so it fits flush with the outer edges of the Bottom Rails and the Side Rails. Then you can apply a protective finish.

Tip: Simple Finish for a Better Bench

To finish our workbench, we simply wiped on a few coats of natural oil finish. Tried and True Varnish Oil is one of our favorites because it’s not toxic and it’s easy to use. An oil finish is great for a bench because it’s easy to apply, it resists glue, and, best of all, it’s easy to renew. As you bench gets worn and scratched, you can just give it a light sanding, if needed, and then wipe on more oil. The MDF will soak up a lot of oil, so you’ll probably need to apply two or three coats to the bench top and shelf. One or two coats should do it for the bench base.